Enhanced hygiene

during UV-C disinfection

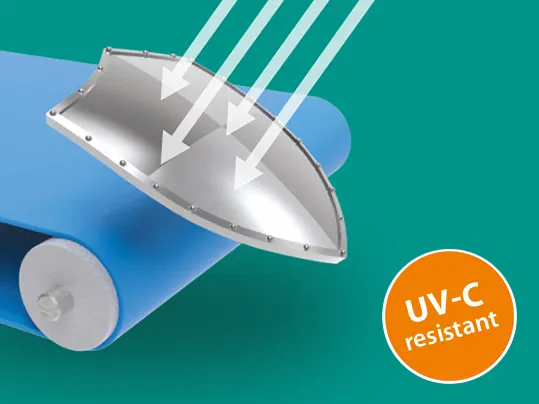

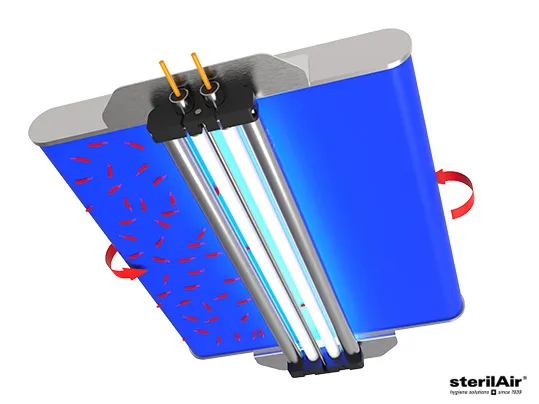

Because it’s very fast and easy to use, UV-C disinfection plays a key role in hygiene technology. Conveyor belts without any UV protection are only of limited use in the process. Their coatings can quickly become brittle, contaminated with germs and turn into a hygiene risk themselves.

All the PVC and PU coatings on Forbo’s conveyor and processing belts (Transilon/Transtex) are made with UV-stabilizing recipes. Premature ageing due to the impact of UV-C radiation (with cracks forming and a tendency to rupture) is now reliably prevented. The belt surface remains intact, isn’t contaminated and is still easy to clean.

Due to the rising demands on hygiene and protecting health in general, the raw materials used have been consistently improved over the past few years. Even if the belts are subjected to UV-C radiation, surface stability is much greater and service lives are far longer. Consequently, processes are more reliable too. When conveyors are operated properly, the contamination risk from the belt is reduced significantly as a result.

UV-C-based disinfection systems are also applied in the food and pharmaceutical industries, where they provide a competitive edge that shouldn’t be underestimated. In many automated production and logistics processes, it’s the cost-neutral use of UV-C-resistant belts that makes the truly safe and economical operation of UV-C disinfection systems possible in the first place.

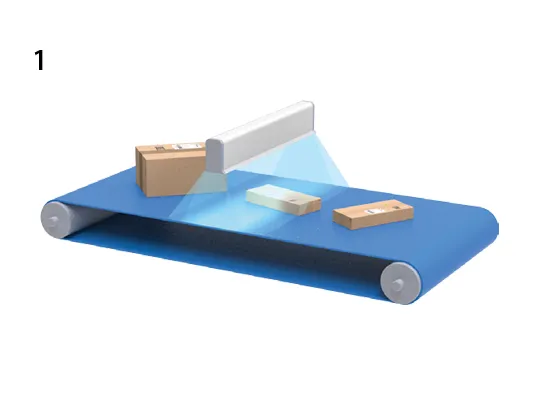

Figure 1 - Intralogistics

Figure 2 - Food industry

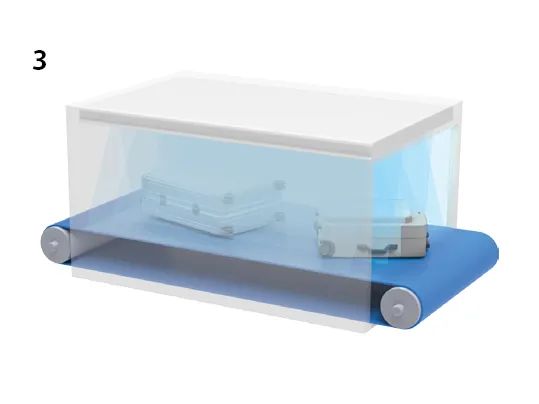

Figure 3 - Baggage handling