eurocol

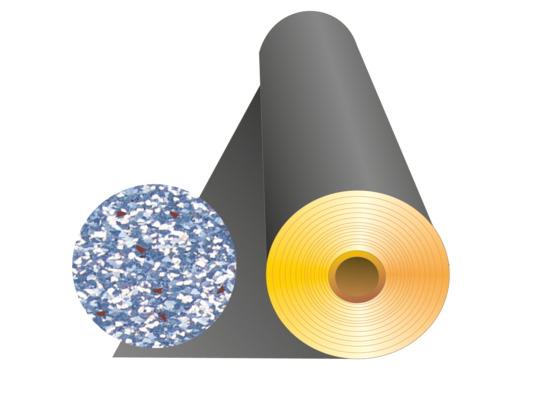

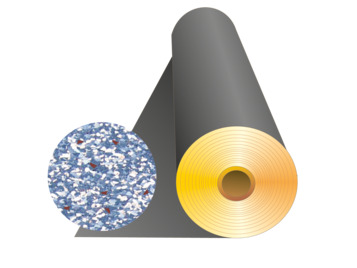

821 EUROFLOOR COMFORT PRO

Step-sound absorbing underlay mat, for floor coverings and parquet. Fire resistant Bfl/S1 (DIN EN 13501-1).