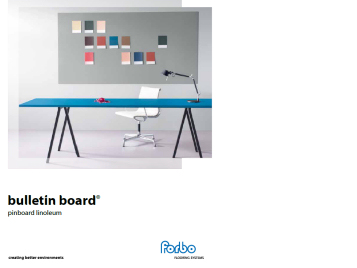

bulletin board

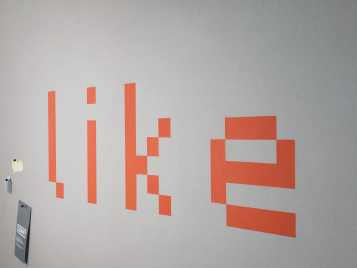

Bulletin Board, for your thoughts...

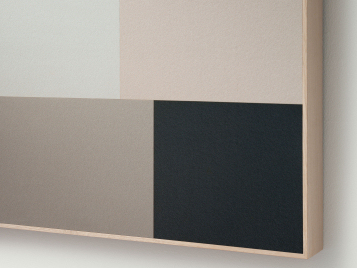

Bulletin Board is the ideal material for pin boards, notice boards and all other surfaces where ideas and information are exchanged.

• All natural pin board solutions

• Resilient and flexible

• Hygienic and bacteriostatic

• Long lasting, timeless and strong

• Versatile and colorful

• Practical and easy

• Sustainable

2209 black olive

| Thickness | 0.24 in |

| Length x Width | ≤ 91.86 ft x 48.03 in |

| NCS | S 9000-N |

| LRV | 5% |

| Recycled content | 43% |