How it's made

• By challenging the way tufted carpet tiles are made, our UK produced Tessera tiles now boast over 50% recycled content.

• We use innovative ultrasonic blades to cut our carpet tiles, which reduces tile waste by 80% compared to the standard press cutting methods.

• We have invested over £1m in a new extruder to ensure that the little waste we generate is recycled back into new product.

• Instead of throwing away yarn ends, we rewind them and tuft them into our Tessera products. We also have several ranges made with Econyl® regenerated yarn. Econyl

• Flotex tiles contain 67% recycled content and Flotex sheet contains 20% recycled content.

• Flotex is the only flocked floor covering to have been assessed under BREEAM and rated mostly A/A+.

• Of all the electricity we buy, 100% comes from renewable sources. This means our carpet tile production sites are part of an effective environmental management system and achieve ISO14001 certification.

How it performs

• Our carpet tiles are quick and easy to clean using a system called Dry Fusion which uses heat, a little water and natural organic cleaners. So you can use less water and fewer chemicals without compromising on appearance.

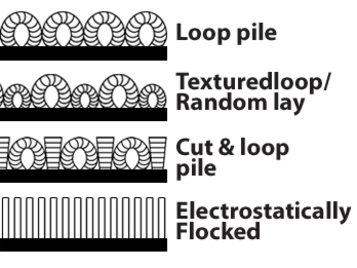

• Our innovative random lay carpet tiles reduce fitting waste to less than 2%.

• Through our back to the floor scheme, we can collect installation off-cuts from Flotex and Tessera nylon carpet tiles and recycle them back into Forbo products at our plants in Preston, Lancashire and Ripley, Derbyshire. Back to the floor

• Flotex benefits allergy sufferers and has received Allergy UK's seal of approval. It releases twice as many allergens on cleaning than standard carpet.

• As a founder member of Carpet Recycling UK, we are also working to ensure that at the end of life, our carpet tiles can be recycled or reused.

.webp)