Step 3 - Production & distribution

Carbon-neutral and zero-waste production

We make products sustainably

Too many flooring solutions come with a carbon footprint, we aim to make flooring without leaving a trace.

We focus on creating products that come with a zero-waste production cycle and are made with 25% or more recycled content products that are as green as possible from design to installation, and which are produced using 100% green electricity where available.

CARBON-NEUTRAL AND ZERO-WASTE PRODUCTION

TOO MANY FLOORS COME WITH A CARBON FOOTPRINT – WE AIM TO MAKE FLOORS WITHOUT LEAVING A TRACE

We don’t just aim to only use sustainable materials for our products. We also aim to make our products as sustainable as possible. That’s why we are working towards a zero-waste production cycle and products made using as much recycled material as possible. We make flooring solutions that are as green as possible from design to end-of-life and are produced using 100% green energy, where available. This is how we produce products that are truly CO2 neutral without the need for off-setting.

70% less CO2 emissions

Circular ready solutions

No greenwashing

Natural raw materials

Producing linoleum

Assendelft (NL) and Kirkaldy (UK)

In Assendelft (NL) we make linoleum floor coverings, bulletin board and finishing material for (office) furniture. Our factory in Kirkcaldy makes linoleum floor coverings like Marmoleum Modular.

Marmoleum, our linoleum brand, is a true environmental evergreen. Made from natural raw materials and produced in a modern and efficient production environment running on green electricity, the production of Marmoleum 2.5 mm is actually carbon negative from cradle to gate.

In our linoleum factories, the vast majority of linoleum waste is re-used in Marmoleum flooring products. Other valuable streams, like jute or furniture linoleum backing paper residuals, are offered to parties that upcycle them into highly valuable or socially responsible products. Installation residues are also collected and added to the recycling system on our sites, contributing to the 43% recycled content in Marmoleum.

Producing vinyl

Coevorden (NL), Reims (FR) and Giubiasco (CH)

Our vinyl is manufactured in ultra-modern and energy-efficient production plants. In Coevorden we make vinyl for applications in residential and commercial areas. Forbo Sarlino in Reims develops and produces acoustic project vinyl and needlefelt floor coverings. Our factory in Giubiasco specialises in the production of homogeneous vinyl tiles such as Allura Colour, and is a leading worldwide supplier of ESD floor coverings.

Vinyl floor coverings are part of a versatile range of products whose technical and sustainable properties have, over the years, undergone a metamorphosis. Next to adding many circular ready constructions this is about improving recycled or re-used content, advanced laquers and dyes, which are nowadays waterborne, while product emissions have been reduced to near zero and harmful substances eliminated. We offer a commercial portfolio of fully phthalate-free vinyl.

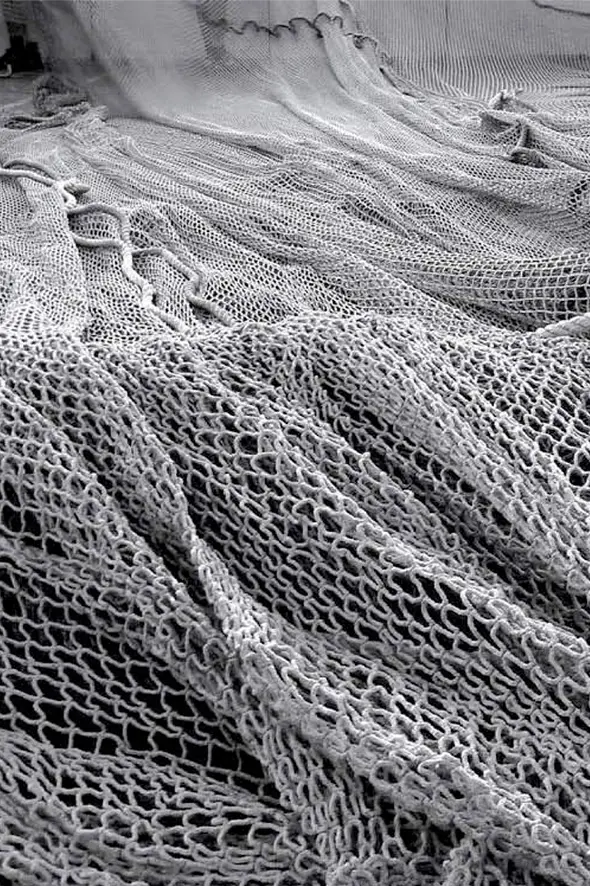

Coral entrance flooring

Krommenie (NL)

Forbo Flooring Coral in Krommenie is the factory where we produce our Coral entrance products. Well-designed entrance flooring not only offers a sustainable solution, they also contribute to the sustainability of the building in which they are used, throughout extending the life cycle of all flooring in the building.

Our entrance floor covering can stop up to 95% of dirt from being walked into the building. In this way, entrance flooring can protect the quality of an interior, lengthen the use of a floor and cut down on cleaning and maintenance costs and the use of detergents. We use yarns that are upcycled from old fishing nets for a large number of our Coral collections. The primary backing of our Coral Welcome entrance flooring is made from recycled PET bottles.

Tessera carpet tiles

Bamber Bridge (UK)

Our tufted carpet tiles collection Tessera is produced in Bamber Bridge. With high-end infinity machines we are able to develop and produce specialised carpet tiles, which are not easy to make.

With a minimum recycled content by weight of 56%, our Tessera tiles are among the carpet tile products with the highest recycled content in the industry. Some of our ranges, for example Create Space 1, even have a recycled content by weight of 70%.

During floor design, we create random-lay tiles so that the parts of the floor that see heavy use can be replaced without this impacting the overall design. We are also experimenting with end-of-life solutions, especially those that involve separating the tiles’ textile layer from their backing.

Flotex flocked flooring

Ripley (UK) and Chateau Renault (FR)

In our factory in Ripley we produce Flotex nylon carpet sheet and tiles. In 2001 we almost completely eliminated our use of landfill by installing the first recycling plant of its kind to convert pre-consumer waste into high performance carpet tile backing. Today this facility processes nearly 50 tonnes of waste a week.

In our factory in Chateau Renault we produce our Flotex design and custom flooring collections. Our factory in Chateau Renault holds two digital printers which print bespoke designs on white Flotex sheet.