Sourcing for circularity

What role does sourcing and raw materials play in achieving circularity in the flooring industry? Find out how Forbo Flooring is leading the way with a forward-thinking use of resources.

To live within the planet’s means and have a sustainable future, we need to rethink how we use its resources. This is where circularity comes in: designing products that can be disassembled and reused at the end of their life, in a closed-loop system.

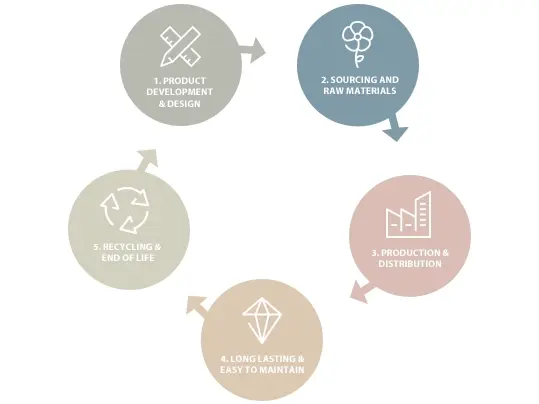

There are five main aspects to be considered when designing circular flooring. We recently looked at the role of product design and development. Of course, you cannot achieve circular product design without considered use of resources. In this blog, we’re looking at how sourcing and raw materials can help achieve sustainable, circular flooring.

The construction sector accounts for 39% of energy-related carbon dioxide emissions, according to a 2019 report. Of that, 11% results from the building materials used. This means that choosing and sourcing the right building materials makes a big impact on a building’s carbon footprint.

When it comes to flooring, architects and contractors have the chance to make a more sustainable choice. Careful consideration should be given to what materials floors are made out of. It is thinking about the carbon footprint of producing the materials, as well as how easily they can be reused or recycled. And of course, choosing non-toxic materials that do not give off any dangerous chemicals is a key factor for both people and planet.

At Forbo Flooring, the materials we choose for our products are carefully considered. We use either natural, renewable materials like Marmoleum or hard-wearing recycled materials like vinyl. 100% of our flooring is made from traceable and safe raw materials. This is part of our mission to ensure our products are kind to the environment from cradle to cradle.

But it’s not just the choice of materials that’s important. Where and how they are sourced plays a big role in the environmental impact of the final product. Forbo Flooring has a rigorous set of criteria its suppliers must meet when it comes to sustainability. We don’t just want to meet the regulations for ethical sourcing: we want to exceed them and provide comprehensive traceability so our customers always know exactly where their flooring comes from.

When we choose new suppliers, the focus isn’t just on price, quality or delivery anymore: instead, alignment with our sustainability and circularity goals is given equal weight. As Rosemary Norman, one of our Procurement Category Managers, explains: "We expect our suppliers to have the same attitudes towards environmental issues as Forbo Flooring. They need to meet all the same standards that we ourselves uphold, including having an environmental management system and meeting the key fundamentals of the SA8000 social accountability standard. We also ask suppliers to sign our Forbo Supplier Requirements Policy. This policy covers all aspects of ethical and sustainable sourcing, including quality management, anti-corruption and raw materials regulations."

Rosemary adds: "Throughout the supply relationship, suppliers need to provide proof of their sustainability activities and we will carry out audits if any risks are identified. They must regularly submit Material Safety Data Sheets to demonstrate compliance with European product safety laws like REACH and we monitor their CO2 reduction programs and sustainability policies on a regular basis."

Traceability and transparency are of the utmost importance to us. We are always clear with our customers about what goes into our products and ensure a transparent supply chain. We have LCAs available for every product group, as well as EPDs and HPDs for individual products. This gives our customers confidence that we’re committed to our sustainability efforts and helps them measure and improve their own impact.

Not only will we uphold our rigorous raw materials standards in the future, but we also expect them to change and develop too. Sustainability and circularity are going to be of increasing importance to our customers in the years to come. In line with this, we aim to increase the amount of bio-based raw materials we use and will always stay ahead of the latest supply chain regulations, even going beyond them to meet the highest standards possible. In this way, Forbo Flooring will continue to lead the way for circularity in the flooring industry.

Next in the series: find out about how we reduce our emissions and waste throughout production and distribution.