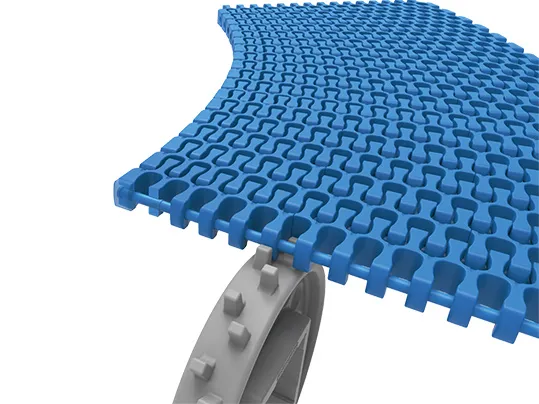

Hanover, September 21, 2020 – A strong modular belt with an innovative hinge pin system for curved and spiral applications.

Forbo Movement Systems is adding series 18 to its modular belt range. The new Prolink belt with a pitch of 25.4 mm (1 in) can be used as a curved and spiral belt and is offered in two variants. They come in blue and white and a choice of two different materials, incision-resistant polyacetal (POM-CR) and polypropylene (PP).

The belts are available with guided hold-down tabs or without guidance on the belt edge. Although the belt, including the hinge pins, is made solely of plastic and therefore very lightweight, it’s very rigid and can handle heavy loads (up to 1600 N in a curve).

The unique pin system is another clever feature. The hinge pins are made of innovative PLX material and perform at a consistently high level, even in wet applications. What’s more – in contrast to the majority of comparable products – the system requires no small closures, therefore reducing the risk of product contamination due to small parts that have been damaged or gone astray. The twin-row sprocket makes reversing operations easy and ensures perfect power transmission.

Another particularly interesting aspect for users: Series 18 is ideal for many existing conveyor configurations and can, in most cases, be installed effortlessly on existing conveyor systems.

Because of the small openings in the belt for small products, it taps into a particularly diverse range of uses in the food industry. With an open area of 44%, series 18 also allows excellent airflow and drainage.

Prolink series 18 is FDA- and EU-compliant regarding the raw materials used and migration thresholds.

Prolink Series 18 Plastic Modular Belt – Powerful Performers that Stay the Course