The customer

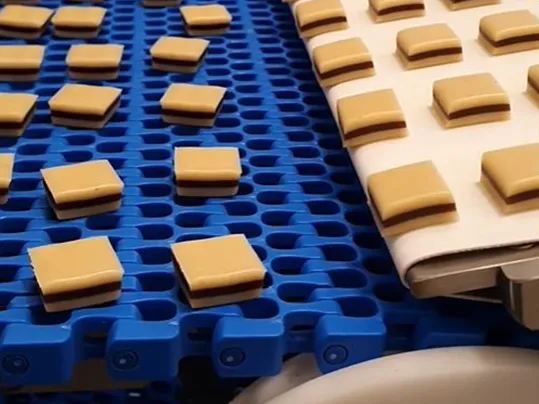

The licorice from Hattesens Konfektfabrik is handmade using traditional methods on the tiny Danish island of Ærø in South Funen. Denmark's only handmade licorice confectionary is vegan, free of gluten, lactose and allergens. Its taste comes from Danish summer berries, exotic southern fruits and cocoa beans. The flavors are packed on both sides of a center core made of 10% raw licorice.