In Germany, Systemservice Kühn GmbH is official service partner of Swiss CAD/CAM cutter manufacturer Zünd Systemtechnik AG. Its portfolio ranges from advice on the cutters, accessories and software to installation, maintenance, repair and customer training, as well as selling spare parts and accessories. Systemservice Kühn GmbH stands apart for its proximity to the cutter manufacturer.

Improving quality and reducing costs and lead times for the end customer

Systemservice Kühn GmbH

Breitenworbis (Germany)

The customer

Which is why the Zünd Germany sales force frequently uses Systemservice Kühn’s premises for cutter demonstrations. This saves future customers from having to go to Switzerland. They can also experience the company’s professionalism up close and personal. As a mid-sized company, Systemservice Kühn GmbH provides an ideal and very flexible response to customers’ requirements.

The application

The requirements of cutting belts in the cutters vary vastly. Should the standard cutting belts in the cutters not meet requirements, Systemservice Kühn will look for other options. And this is where the belts from Forbo Movement Systems come in. Following cutting tests and thanks to Kühn employees’ in-depth expertise, Systemservice Kühn can then provide a solution and offer all customers the right Forbo belts for their needs. Systemservice Kühn can also handle belt fabrication.

Our solution

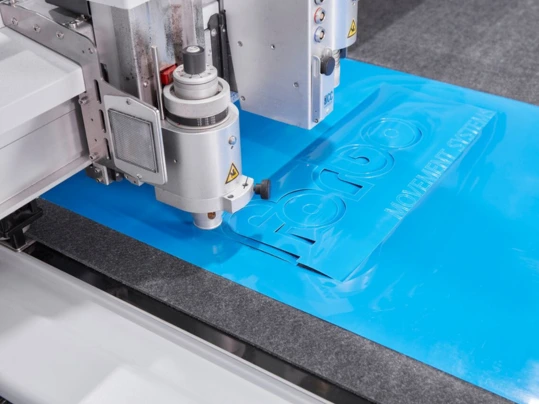

The new, fiber-based Novo 30 HAP-HC+ black cutting belt is ideal for cutting textiles, leather for making shoes or handbags, for wood, plastic, paper or cardboard. At a width of up to 3,500 mm, it’s produced without a center seam. Seams are always a challenge during cutting because the height of the cutting belt can differ. In this case, the lack of a seam in broad cutters is a particularly big advantage. The belt also offers excellent air permeability for affixing the material on the belt by vacuum suction. Due to its high air permeability, it also reduces the vacuum turbine’s energy consumption.

The new belt has already had a good track record in various advertising technology applications, such as cutting leather for give-away pencil cases to cardboard displays and cutting functional textiles for sports shirts.

Forbo Movement Systems partnered closely with Systemservice Kühn to develop the new belt. The variety of testing options due to all the applications at Systemservice Kühn has helped to optimize the belt’s design.

Different cutting belts in use

However, fiber-based belts, such as the Novo 30 HAP-HC+ black, are not suitable for some cutting applications.

“For example, in cleanroom applications in medical-product manufacturing, such as IV bags or in fuel cell production. PU-coated belts like Forbo’s E 6/2 U0/U18 STR transparent cutting belt are ideal in these cases. Because the fabric fibers are sealed, the cut material isn’t contaminated by fibers etc.,” says Michael Kühn, founder of Systemservice Kühn GmbH (on the right of the photo with CEO Sascha Nörthemann).

The result

Our team worked closely with Systemservice Kühn to develop the new Novo belt in a practical way. All of which served to boost the existing relationship. For long-term testing, both sides drew on an application belonging to one of Kühn’s major advertising technology customers. As a result, Systemservice Kühn has satisfied customers because it can choose from belts tailored to customer requirements.

“We benefit enormously from collaborating with Forbo Movement Systems. Teamwork resulted in customized solutions that match our customers’ requirements perfectly. Forbo’s flexible response to our needs deserves special mention, whether it involved developing the new Novo belt or selecting the right cutting belts for specific applications. This collaboration, geared to real-world conditions, helps ensure we have very satisfied customers. Which, for us as a customer-centric service company, is exceptionally important.”

Sascha Nörthemann, Kühn Systemservice GmbH CEO