The customer

An online, mail-order business with a wide range of products and more than 175 fulfilment centers. In 2020, it opened a new fulfilment center with floorspace of 4,200 square meters.

Service

Germany

An online, mail-order business with a wide range of products and more than 175 fulfilment centers. In 2020, it opened a new fulfilment center with floorspace of 4,200 square meters.

The conveyors used are fitted with Forbo Movement Systems’ belts. However, the fabrication equipment, such as presses and punch presses, were sourced from a competitor.

Forbo’s service technician pointed out that storing the roll material on the floor wasn’t ideal and that the punch press only produced mediocre results. What’s more, the air-cooled press would be too wide for the majority of applications. Hardly any of the company’s staff had any previous experience with fabricating conveyor and processing belts correctly.

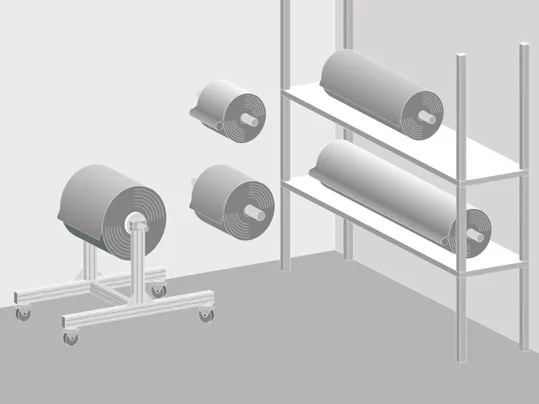

To ensure the conveyors were available 24/7, we suggested and made the following improvements. We supplied moveable mounts with CE labeling as reelers for the roll material.

The existing presses were then replaced by the Blizzard 160/800 heating press (a lightweight, fast-cooling combo press) and a smaller one, the SM-HP 150/100 including accessories and electronic control systems. A fitting tool for mechanical fasteners was also supplied for emergency repairs. Two, pre-fabricated replacement belts with plastic fasteners were also provided for emergencies. And finally, we gave in-depth training to the maintenance staff.

The services we provided guarantee the round-the-clock availability of the conveyors that the business required. Expensive downtime is minimized and the conveyor runs without a hitch at all times.

Our staff are well trained and have exceptional skills as well as state-of-the-art equipment when it comes to belts and service. They only use processes and materials that have been approved in order ensure perfect results and long service lives.