Purchasing customer is SSI SCHAEFER, which, among other things, manufactures on behalf of fashion retailer H&M, is one of the world’s leading providers of intralogistics solutions, materials handling and storage systems.

At around 70 operative companies and at seven domestic and international production sites globally, SSI Schäfer develop innovative concepts and solutions for their customers’ industries.

How to Extend Belt Life and Reduce Costs

SSI Schäfer for H&M

Milton Keynes (UK)

The customer

Within the UK the Head office is located in Towester and the warehouse in Milton Keynes. A total of over 300 people are employed in the UK.

Our sales team and SSI SCHAEFER design engineers work closely with customers to develop customized storage solutions that help maximize their operational efficiency.

Application

The conveyor transports parcels from stationary and online retail from A to B as part of the order fulfillment process. In the high-frequency, high-speed application under high load, the electric motors were stressed beyond the design specification. This led to overheating and premature wear of the belts, with frequent belt changes every six months.

.webp)

Our belt solution

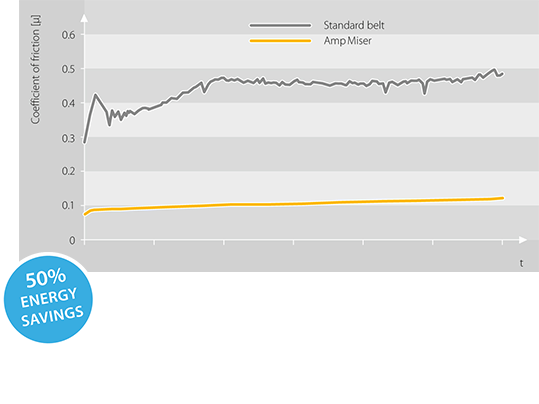

We advised AMP Miser would reduce load on electrical motors and thus wear on all other parts such as belt, bearings, rollers etc. SSI Schaefer witnessed significant reduction in load on electrical motors, comfortably bringing them back within design specification and have had no need to change belts since, now in excess of 24 months.

Both SSI Schaefer and H&M are delighted with the reduction in the load and wear on the conveyor, most notably the significantly improved energy performance and longevity of the Amp Miser belts.

more information about amp miser

Barry McSweeney, R&M Engineering Manager at SSI Schäfer:

"We've experienced remarkable results after implementing the Amp Miser belts on site. We initially faced significant challenges with conveyor motors tripping out due to overcurrent and belts wearing out within just a few months in high-demand, high load sections of our system."

And he explains:

"On Forbo's recommendation, we decided to test the Amp Miser belts, even though we weren't 100% convinced at first. But the result was an absolutely positive surprise:

• The Amp Miser belts effectively reduced the current draw of the motors to such a degree, a review for the motors sepcs was no longer required, preventing overloads and reducing the running costs.

• The belts have significantly increased the life expectancy, lasting more than 300% longer than standard belts. While our standard belts typically required replacement within as little as a year, the Amp Miser belts installed in May 2021 have now run continuously for over 3 years and 6 months and still counting without any indication of requiring replacement. "

In conclusion, Barry McSweeney emphasizes:

"The combination of improved motor performance and extended belt life has provided considerable cost and maintenance benefits for our site."