The customer

In November 2019, after less than one year of construction time, the American company opened the Tesla Gigafactory 3 in Shanghai, China.

Tesla

Shanghai (China)

In November 2019, after less than one year of construction time, the American company opened the Tesla Gigafactory 3 in Shanghai, China.

Electromobility is becoming increasingly important in the automotive industry – in every part of the world. Tesla, one of the best-known US-American electric car builders, is also feeling this. That is why the company opened its doors in Shanghai.

In the automotive industry, car body presses are a central unit in the production process: There, sheet metal parts are turned into doors, fenders or car roofs. In order to deform the sheet metal more easily, it is first heated up, then sent to the press and then conveyed for further processing under extrem conditions.

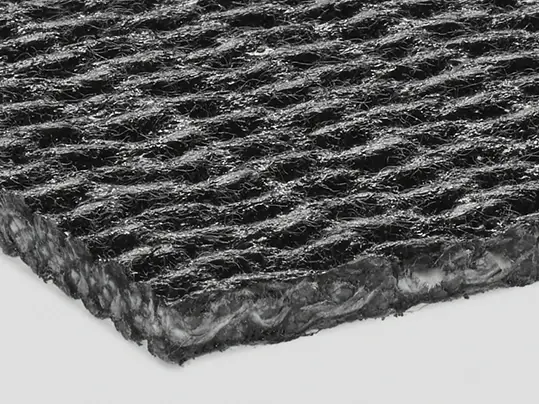

The Transtex belt PVK150 FSxFS-NA black FR with Heavy interwoven PVC used in the Tesla Gigafactory 3 measures 44.25×1.6 meters. At the start of the conveyor belt, there is a robot arm that places the pieces of metal on the belt.

Movement Systems is making an important contribution towards production with the conveyor belt from Siegling Transtex PVK150 FSxFS-NA black FR Art.-No. 908125. This is a robust, fabric-based conveyor belt for extreme production conditions, particularly in the field of metal processing and in combination with heat. These are the exact conditions that apply to the application area in the Tesla Gigafactory 3 in Shanghai.