About Siegling Transilon

Siegling Transilon conveyor belts and processing belts for speeding the flow of goods and for economic processing in the light materials handling industry.

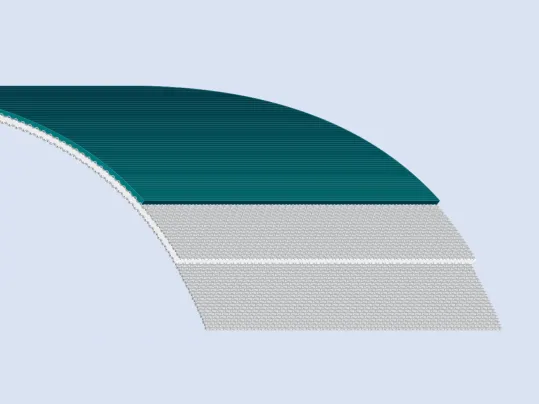

Certain conveying and processing tasks require mechanical, physical or chemical belt properties which are made possible only by special production processes, combination of materials or finishing.

The standard Siegling Transilon construction consists of polyester fabric as tension member with synthetic or elastomer coatings. Siegling Transilon is used successfully in industrial, commercial and service companies worldwide. The standard product range includes over 160 various conveyor belt types and constructions for the most diverse of application requirements.

We offer special product ranges for numerous industries and applications.

Siegling Transilon offers the following properties and benefits, depending on the belt type:

The properties The advantages virtually stretchless small take-up ranges are possible dimensionally stable unaffected by fluctuations in humidity and temperature low-noise environmentally friendly by reducing noise emissions longitudinally flexible drums and knife edges of small diameter may be used laterally stiff wide belts run flat light and thin even long belts can be handled easily rugged tough and wear-resistant, wide range of applications troughable adapts easily to troughed rollers flame-retardant complies with EN 20340 and DIN 22103 highly conductive measured in accordance with DIN 22104 and ISO 284

Aiming for sustainable processes is integral to our global corporate strategy.

We achieve more sustainability in terms of conveying, shipping, and processing with conveyor and processing belts whose tension member is made of recycled PET.

At the same level of quality as the primary material, yarns made of recycled polyester (rPET) save valuable raw materials. At the same time, the energy consumed to make them, and therefore carbon emissions, is much lower. First-class tension member fabric for fabric-based conveyor belts are made from these yarns.

Transilon ECOFIBER

Amp Miser are the energy saving conveyor belts from Forbo Movement Systems.

TÜV Rheinland has certified the savings potential of Amp Miser belts. Amp Miser has also recieved the Best of Industry Award 2023 in the Best Sustainability Project category for its positive, climate-friendly impact.

With conveyor belts from the Amp Miser series, you can reduce your electricity consumption, cut energy costs and reduce your CO₂ emissions.

Learn more about Amp Miser

.webp)

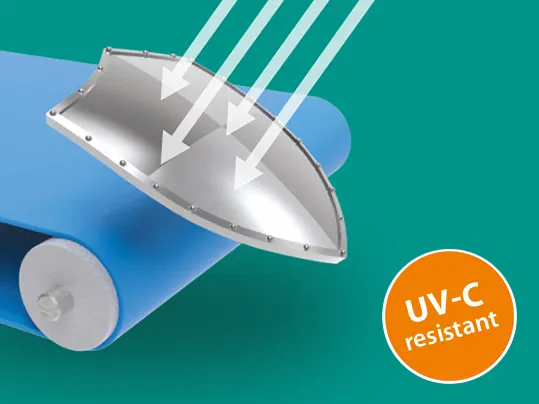

All the PVC and PU coatings on our conveyor and processing belts (Transilon/Transtex) are made with UV-stabilizing recipes. Premature ageing due to the impact of UV-C radiation (with cracks forming and a tendency to rupture) is now reliably prevented. The belt surface remains intact, isn’t contaminated and is still easy to clean. For enhanced hygiene during UV-C disinfection

Learn more aobut UV-C-resistant conveyor belts

We process the Transilon belts for specific use in your production process. Precisely tailored to your requirements, we prepare your conveyor belts for use in one of our worldwide finishing centers. This includes profiles, sidewalls, belt edge sealing, markings, perforations and much more. If you have special requirements for the belts, talk to us - we are also happy to break new ground in belt finishing.

We can also provide you with technology and know-how for endless splicing.

More information on belt engineering

.webp)