Positive Drive

Siegling Fullsan Series

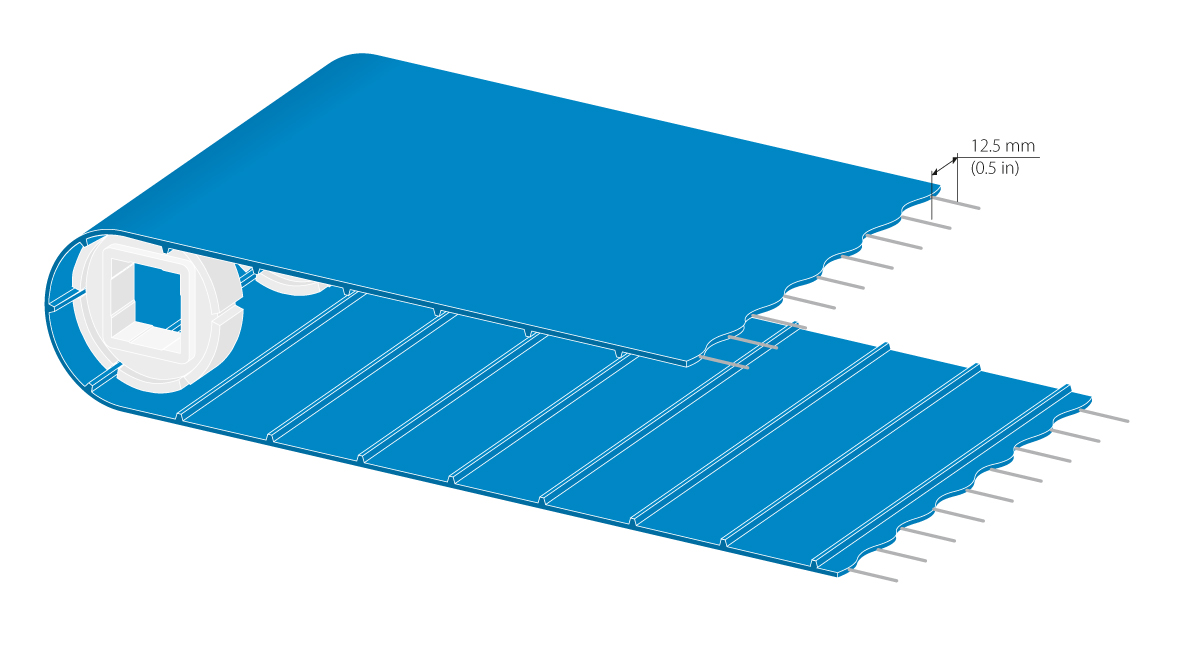

Form-fit sprocket drive is used to transmit power in Siegling’s Fullsan Positive Drive belts. As a result, the belts can be positioned exactly and slippage will not occur. The underside of the belt features teeth across the whole width.

Fullsan Positive Drive Pro (PD+) comes with embedded, lengthways aramid cords. The flat polyurethane belt has continuous teeth across the whole belt width.

The positive drive guarantees reliable transmission of the drive forces and precise positioning. Sprockets can be mounted in any position on the drive axle as required.

The Pro version (PD+) with embedded, lengthways aramid cords increase the tensile force, minimizing belt elongation in the process. As a result, the belts are ideal for long conveyors and heavy loads.

The high C3 value and low elongation at fitting is another benefit of the reinforced Positive Drive series. The high C3 value enables much heavier loads on the belts, compared with the non-reinforced versions commonly available on the market, and guarantees a high level of dimensional stability.

Flexible, robust, and durable: To give the material its excellent hygiene and mechanical characteristics, the belts are manufactured with first-class raw materials to high standards.

Compliant and safe: All Fullsan products meet the current FDA and EU regulations.

Easy to clean: Fullsan is particularly easy to clean due to its closed, smooth surfaces and hydrolysis-resistant polyurethane. Short intervals between cleans, UV-C disinfection, and mechanical belt cleaning processes won’t harm the belt.

Customized fabrication: To prepare it perfectly for the application concerned, profiles and sidewalls can be added to Fullsan. Matte and shiny belt surfaces offer the required release properties.

Flexible, Robust, and Durable

+ compliant and safe

+ easy to clean

+ customized fabrication

___________________________

= Exceptionally hygienic and economical to operate

Fullsan Flat and Flat Pro are designed to cope with a broad range of temperatures from -10°C/14°F to +70°C/158°F for all steps in the process: