eurocol

FORBO QUICKFIT

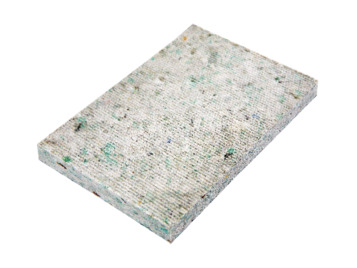

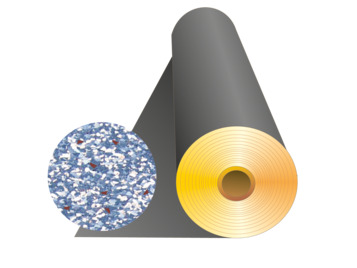

Underlay panel, Decoupling of floor coverings, | can be removed without damaging the substrate, joint-free up to 100 m²