Килимові планки Tessera

Модульні покриття підлоги стають все популярніші у форматах планок та плитки, оскільки вони дозволяють створити необмежені комбінації дизайну на підлозі - від яскравих та складних до мінімалістичних та сучасних.

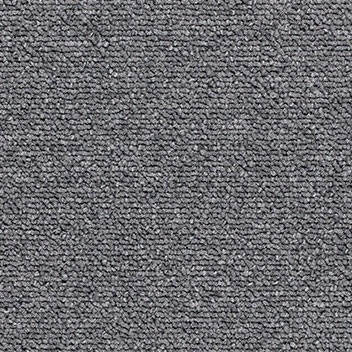

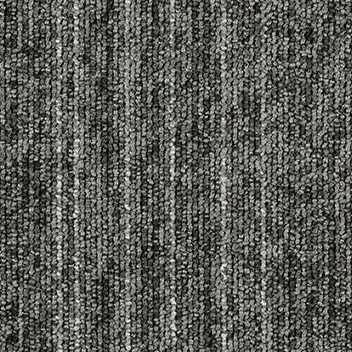

Tessera Layout & Outline

Динамічна палітра кольорів Tessera Layout є універсальним вибором сучасних нейтральних кольорів у поєднанні із напрваленими яскравішими тонами. Кольори можуть застосовуватись як окремо та і в поєднанні.

Tessera Outline - смугаста килимова плитка, кольори якої ідеально відповідають 2 кольорам Layout. Поєднуючи Outline та Layout ви отримуєте безмежний вибір комбінацій на підлозі, можливість зонування, створення переходів чи зв'язків.

Tessera Basis Pro Phase

Планки Tessera Basis Pro Phase пропонують смугастий градієнтний дизайн у 6 нейтральних та 6 акцентованих кольорах. Планки Tessera Basis Pro Phase містять аналогічні конструкції волокон та кольорів, що й плитки Tessera Basis Pro, що надає модливість поєднувати дві колекції, легко створюючи різноманітний та гнучкий дизайн простору.

Градієнтний дизайн по ширині планок 100x25 cm довзоляє створювати переходи від світлого до темного і навпаки. Або ж ви можете рандомно монтувати планки для створення випадкових комбінацій переходів тонів.

Tessera у поєднанні із Allura Flex LVT

Колекції килимових плиток і планок Tessera та вінілових планок і плиток Allura Flex LVT створені для поєднання. Вони монтуються разом швидко та легко із застосування однакового фіксатора.