Hanover, Germany, June 21, 2022 – Very robust, heat-resistant folder gluer belt added to the Siegling Extremultus product portfolio

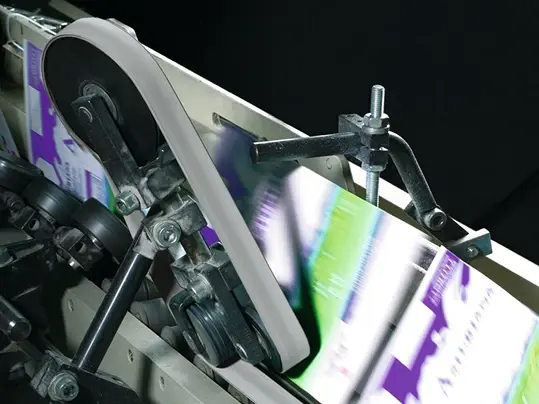

During production of cardboard packaging, a top and bottom belt guide the cardboard sheet through a folder gluer. In the process, the belts reach speeds of > 12 m/s. A special application is manufacturing aseptic cartons for liquids (e.g. milk, cream, juice etc.). In this case, the additional step required to seal the carton is carried out under high temperatures in a special module (known as a sealer) with hot air of up to 600°C. The underside of the belts is cooled down to stop them heating up as much.

To serve this particular application, Forbo Movement Systems added a new Extremultus TR 10P-30 FBRC/NSTR black/gray FDA belt (art. no. 855651) to its Siegling Extremultus portfolio. A leading global manufacturer of cartons for liquid foods (e.g. milk or juice) is already using it successfully. The new high efficiency belt has a Medium Grip top face coating. Despite the exceptional conditions that apply to the application, the grip’s maintained throughout the belt’s service life. What’s more, in contrast to rubber coatings, this coating doesn’t tear. The new Extremultus TR 10P-30 FBRC/NSTR black/gray FDA folder gluer belt is also very easy to track after belts have been exchanged.

The product complies with requirements for direct contact with foodstuffs specified in the FDA 21 CFR and EU 10/2011 and EC 1935/2004 standards. As a result, it’s perfect for use in the food and beverage industry.

Twice the Service Life for the New Siegling Extremultus Power Transmission Belt