Tobacco Industry

Forbo conveyor and processing belts are in operation from the tobacco harvest to conveying the bales, to preparing the tobacco and producing the cigarettes, to conveying packaging ready for sale.

The special challenge placed on the belts during green leaf processing, primary processing and secondary processing is the constant change in the nature of the tobacco, temperatures and the conveying required. Forbo belts are successfully used as fabric-based belts (Siegling Transilon), or plastic modular belts (Siegling Prolink), as power-transmission (Siegling Extremultus) or even timing belts (Siegling Proposition), in a number of different applications. Various customised finishes, such as profiles and sidewalls, as well as accessories like belt scrapers, offer further options specific to particular applications. In conjunction with our global service the result is a reliable full range of belt products.

Our Siegling Transilon conveyor belts of course comply with the stringent pyrolysis requirements placed by the tobacco industry. They also fulfil the regulations on plastics for unpackaged foodstuffs (EU, FDA) which equally apply to unpackaged tobacco when conveyed.

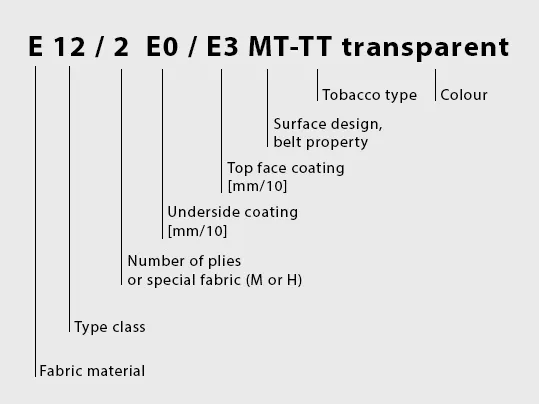

All Siegling Transilon belt types for the tobacco industry have the suffix TT in their name (TT = tobacco type).