Hanover, November 11, 2020 – Wear-resistant processing belt with polyurethane coating developed by Forbo Movement Systems for ultrasonic cutters.

When composites, floorings, leather and sports articles (e.g. snowboards) are cut, conveyor belts with special surfaces that don’t make the products dirty are recommended.

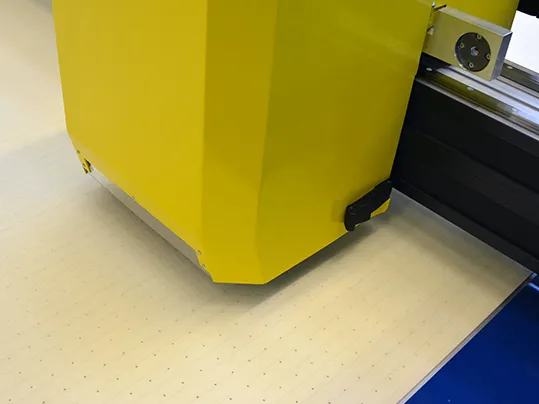

The Transilon E 6/2 U0/U18 STR transparent belt (art. no. 906892) was custom-developed for a renowned ultrasonic cutter OEM. The new conveyor belt has an exceptionally thick and tough polyurethane surface with Shore A 92 hardness and an excellent track record in ultrasonic cutters.

The coating thickness of approx. 1.8 mm protects the tension member from damage during cutting because the blade can only penetrate the coating up to a depth of 1.2 mm.

The STR surface pattern ensures good grip so that products don’t slip. As well as using it as a cutter belt, this type’s outstanding chemical resistance and incision-resistant surface make it ideal for the automotive or metal industry, i.e. when conveying sharp-edged metal or cast parts.

New, Ultra-Strong, Transilon Cutter Belt