Confectionery production

Making confectionery is an art in itself. And anyone peeking behind the scenes will realise the craftsmanship and dedication that goes into each sweet treat.

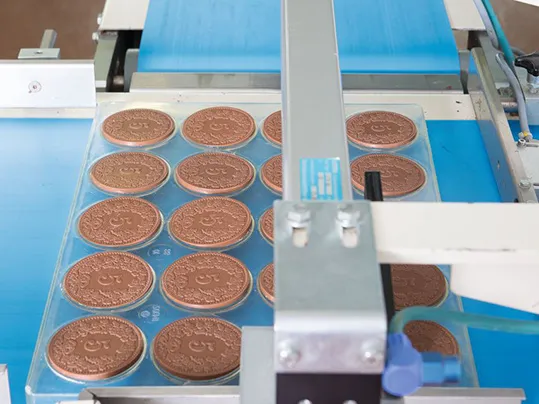

The production process is a real challenge, especially for sticky and greasy products such as chocolate bars, filled chocolates, candy or wine gums. It’s not just the ingredients and skills of the people making them that count, but the technology as well.

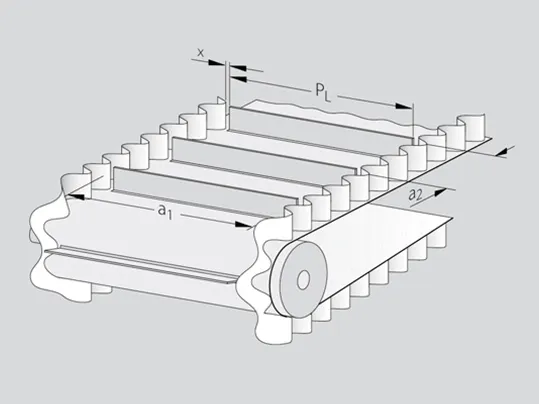

Conveyor belts bring the confectionery from one stage in the process to the next. They also ensure that product quality is maintained along the way. To do so, special top face coatings and surface patterns are required. These must ensure precise conveying, have good release properties and be easy to clean.

Our comprehensive portfolio of fabric-based conveyor and processing belts, as well as homogenous belts, allows us to meet these very requirements. As a result, they help guarantee that each piece of confectionery is perfect.

Your confectionery stands apart for its texture, taste, and superb appearance? That’s perfect. Various custom-developed conveyor belts throughout the production process guarantee your confectionery stays that way. Ultimately, they ensure that your products look as desired and are tempting to eat.

But which belts are particularly ideal for your products, boost your productivity, and comply with the hygiene standards required?

“Confectionery, from bars of chocolate to filled chocolates, present particular challenges during manufacturing. Picking the right conveyor belt is crucial because each product has different characteristics. We’d be happy to help choose the best belt for your requirements and guarantee flawless production.”

In all areas of the food industry, Siegling Transilon belts are real all-rounders for special conveying and processing tasks.

To the Siegling Transilon Belts product finder

Exceptionally resistant to oil, grease, moisture and bacteria, our homogenous conveyor belts are geared to all unpackaged food processes.

Siegling Fullsan – the powerful, more hygienic solution

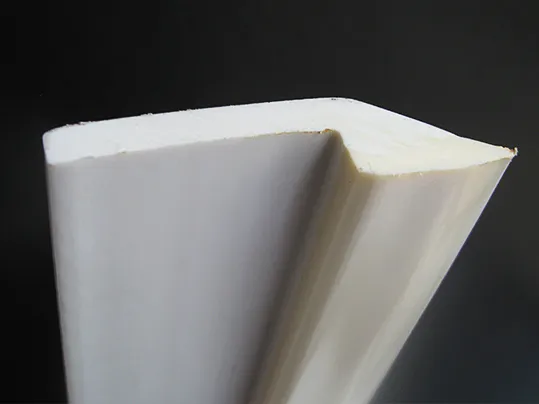

It’s vital to prevent lint forming on conveyor belt edges. We do so via a special fabric, a unique bond and optimized fiber lengths so that there's no fraying – even on unsealed belts.

As a result, our Frayfree belt types guarantee safety, so crucial in the food industry, and meet all hygiene standards.

More information about our Frayfree belts

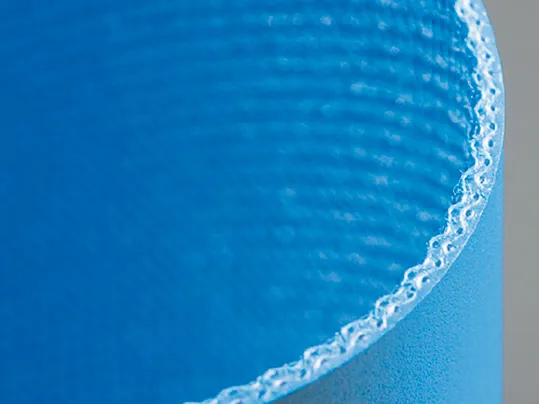

Do you need superior hygiene in plastic conveyor belts with fabric tension members? Firstly, our Smartseal belt edge sealing prevents oil, grease, water, and bacteria from penetrating the fabric. Secondly, this sealing method prevents lint from forming on the belt edges.

More information about our belt edge sealing

Are you seeking a gentle and effective way of cleaning the conveyor belts on your confectionery production lines? Our urethane belt scrapers allow thorough cleaning of belt surfaces and splices while treating the surfaces carefully at the same time. These durable scrapers come in various colors and in a version with metal-detection capabilities (MD).

White belt scrapers

Beige belt scrapers

Blue belt scrapers

Blue belt scrapers with metal-detection capabilities

In the food industry, bulk materials, such as confectionery, flour or sugar, need to be conveyed very hygienically and without any product loss. We do so by providing side walls, which are easy to clean and can withstand oil and grease.

More information about the side wall range

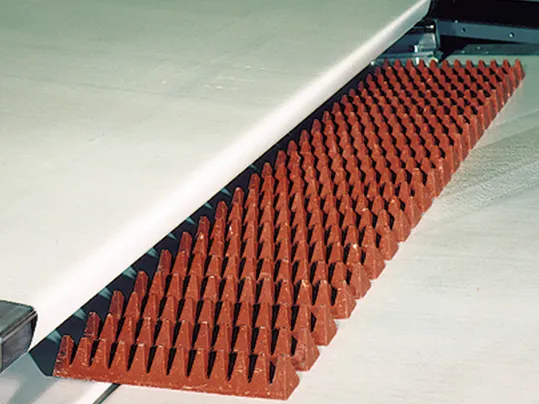

The unique structure of our cutting belts guarantees excellent cut and punch resistance when cutting confectionery. These HACCP belts’ durability makes them a high-quality and economically attractive solution.

More information about cutting belts

Do your processes require precise conveying? If so, the HighGrip coating on our Transilon belts keeps products securely in place. They grip the products gently but securely and release them again at the right time. HighGrip is a special surface coating that gets hold of the products. It’s also easy to splice and offers a robust top face. It’s particularly ideal for inclined conveying.

More information about our HighGrip belts

Confectionery can be sticky, greasy, or covered in sugar and all items behave differently on conveyor belts. Therefore, to ensure flawless production, the conveyor belts require special release properties to guarantee the product comes off the belt easily.

Depending on the top coating’s characteristics, top-face patterns, and the nature of the confectionery (greasy or sticky), we offer customized conveyor belt solutions with exceptional release properties. For instance, coating materials with low surface tension are naturally nonstick and ideal for conveying sticky or sugar-coated confectionery.

Our experts can tell you anything you want to know about confectionery manufacturing.

To the contact form