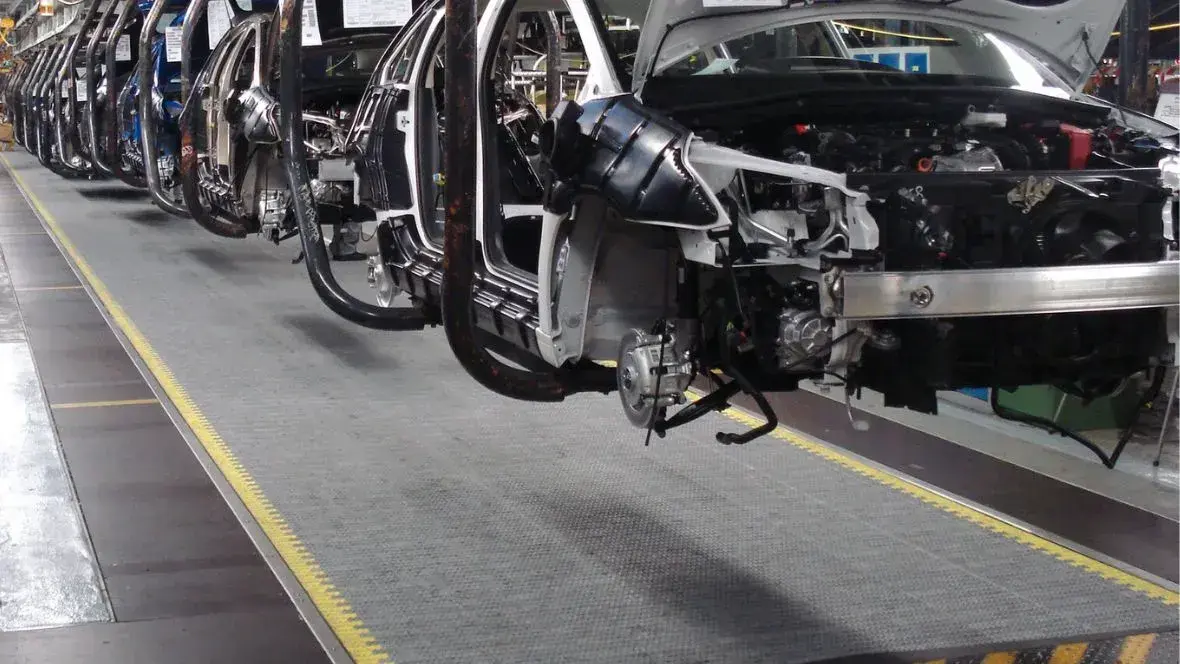

Performance all along the line

Experience enhanced production processes with Siegling Prolink, custom-developed for the automotive and tire industries’ requirements. Siegling Prolink’s top quality guarantees your plants operate like clockwork.

Siegling Prolink plastic modular belts are geared to the demands of automotive and tire production. We listen to our customers’ requirements and apply our expertise. As a result, the belts respond exactly as expected.

“Forbo has proven expertise and a solid track record in the automotive and tire industries. As a comprehensive supplier of conveyor and processing belts, Forbo offers everything under one roof.”

Andreas Brackmann, Director of Global Business Development

To prevent downtime, all belts need to meet top quality standards. Our belts are durable and meet the demands of automotive and tire production consistently.

First-class efficiency: Siegling Prolink is designed to top engineering standards. As a result, belt maintenance intervals and service lives are longer and your production more reliable due to less downtime.

Designed for heavy-duty usage and long conveyors: Outstanding tensile strength and rigidity make the belts tough.

Reliable and efficient components: Highly conductive, flame-retardant belts mean no static charge and safe usage.

Efficient conveyor design: Low conveyors enable very compact belts.

Minimal downtime: The belts’ durability, fast service and modules that are easy to replace and repair cut downtime.

Low maintenance costs: First-class engineering means our conveyor belts need very little maintenance.

Energy saving: Low-friction, silicon-free belts decrease energy consumption and costs.

Our belts are made to last and last. As a result, they help to reduce waste. Their sophisticated designs have low frictional resistance. Which cuts energy consumption. We use recyclable belts to encourage a sustainable circular economy. Some of our modular belts are also made of recycled materials. As a result, we’re actively protecting the environment.

read all about it in our digital Sustainable Products magazine

Our service team looks after your plastic modular belts and your production line as a whole. Forbo Movement Systems delivers a flexible range of services, from quick on-site deployment to various additional options to end-to-end servicing. Our employees have extensive belt expertise and service skills, superb tools and equipment. What’s more, they only use approved processes and materials. So that your production lines run perfectly.

Click here for more information on our services

Better productivity: We custom developed Siegling Prolink for the automotive and tire industries. And it provides the top performance these sectors require.

Innovation and expertise: Forbo offers cutting-edge engineering, consistent innovations and proven expertise in the automotive and tire industries.

Comprehensive belt solutions: Forbo has a wide range of conveyor and processing belts. You receive customized solutions and save time spent on procurement.