The Cookie and Biscuit Production

Producing cookies or biscuits is a fascinating process. Superior precision and the right technology are married with traditional baking skills.

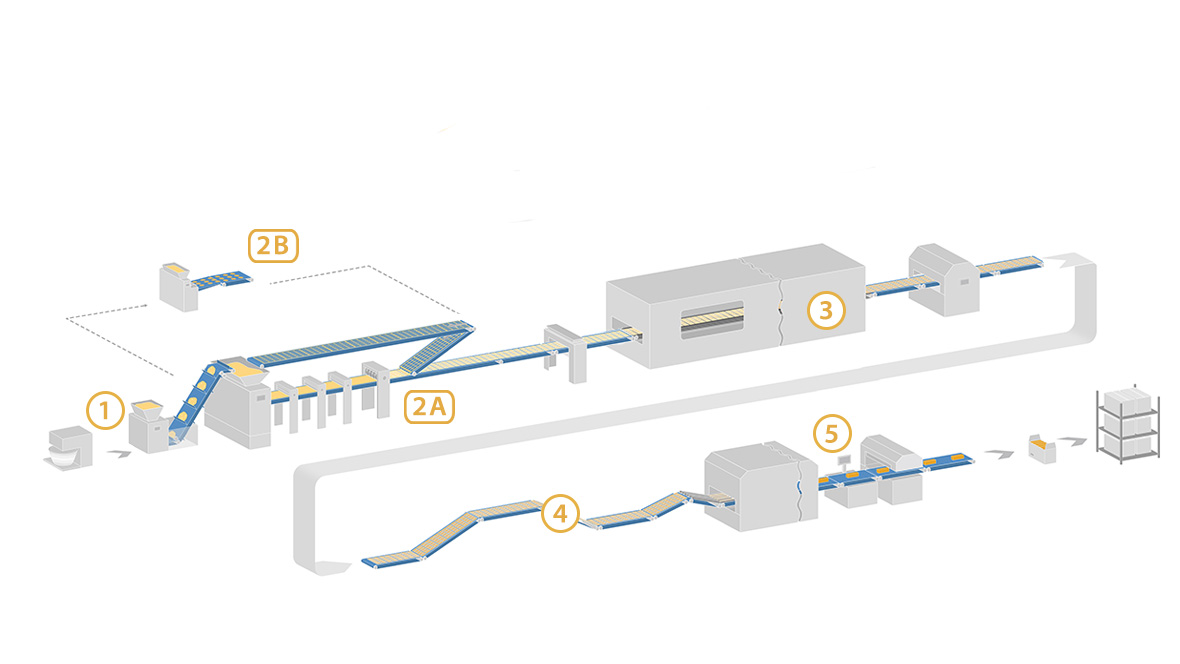

Following careful preparation, a special feeder conveys the dough on for processing. Cutters or presses lend the dough its characteristic shape before it’s baked and turned into a golden-brown treat. After cooling, cookies or biscuits are subject to stringent quality controls. They are then packaged and sent on their way to customers.

Conveyor belts play a key role in the process because they take the cookies or biscuits to the next stage on the production line. We’ll show you the ideal belts for your dough and production line – starting with dough processing to in-feed all the way to packaging.

To get the dough into the shape required, hoppers feed dough into the production process An inclined conveyor belt takes the dough to section where sheets or other shapes are made.

Technical Requirements of the Belts

Conveyor belts that grip and release dough well, while meeting rigorous hygiene standards, are perfect for a production line. Depending on the conveying angle, we recommend patterned belts. Tiny return radii also facilitate dough release at the end of the conveyor and transfer the pieces of dough gently.

Our Solution

For dough in-feed, we recommend our standard Transilon PU or polyolefin belts and innovative homogenous Fullsan belts too.

Thanks to diverse coatings and patterns, these food-grade belts grip and release the dough perfectly, while meeting top hygiene standards. These easy-to-clean belts are MHLW-, EU- and FDA-compliant. As an option, we can add belt edge sealing (Smartseal) to these belts.

Contact us if you’d like to know more

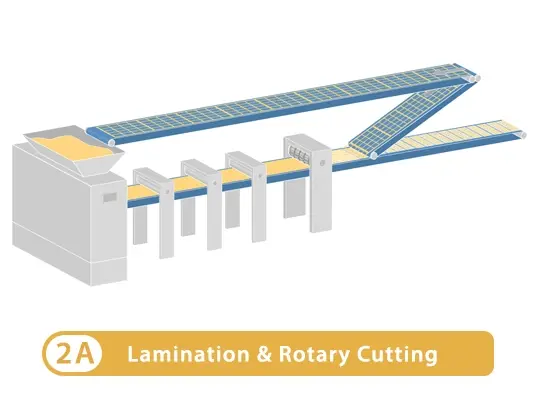

There are several ways cookies or biscuits are shaped. The rolled-out dough is either shaped and cut out, or more complex processes, such as folding, rolling and then cutting out the dough, are applied.

The rest of the dough is then returned to the dough hopper and fed back into the process (see Rotary Molding section 2B).

Technical Requirements of the Belts

These processes need food-grade belts with exceptional positioning accuracy and that grip and release well.

For perfectly shaped cookies or biscuits, the belts need to be incision resistant, track straight and operating at a steady speed.

Small end radii (knife edges) are needed for transferring the formed pieces of dough.

Our Solution

We offer multiple fabric-based, elastic, and homogenous belts from the Siegling Transilon or Siegling Fullsan series. These are ideal for making or cutting out sheets of dough. They are food-grade belts with good grip and can handle knife edges and cutting out dough.

We recommend uncoated, urethane belts, or ones coated with cotton for forming the dough into shapes.

Laterally stiff belts with incision-resistant coatings made of PU or polyolefin are the top choice for cutting out and forming dough. To guard against belt abrasion, we can add belt edge sealing (Smartseal) to many of the belts as an option.

These belts’ good release properties minimize the need for flour as a release agent. The easy-to-clean belts are also EU- and FDA-compliant.

Clean splices ensure that no markings are left on the bottom of products. If required, these splices can also be made on the machinery in situ. We can offer you various splicing methods and tools for fabric-based, elastic and homogenous belts.

Contact us if you’d like to know more

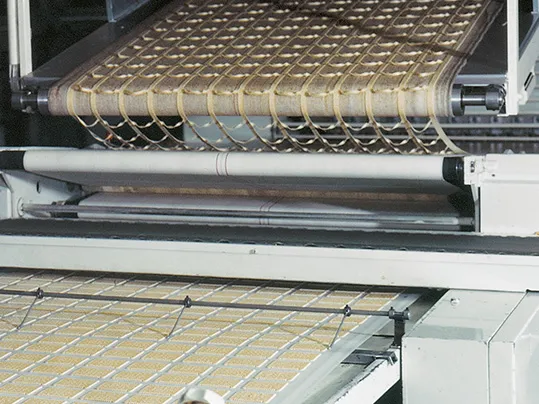

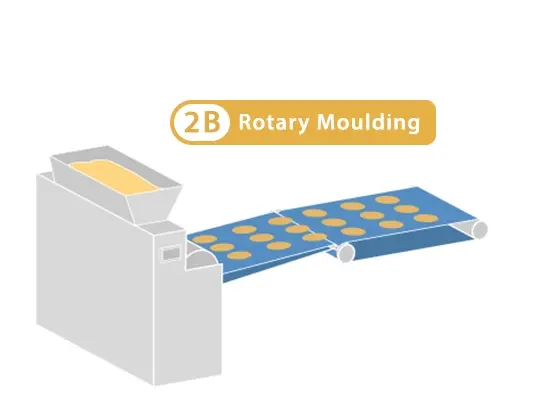

Rotary molders are another way of getting your dough into shape.

The dough is conveyed on the belt and another roller presses the dough into the hollow sections on the rotary molder. Once they come into contact with our conveyor belts, the pieces of dough fall out of the molds in the roller. This is a key to ensuring the process is successful.

Technical Requirements of the Belts

Belts destined for rotary molders need to be food safe and have relatively high belt tension. To transfer the shaped pieces of dough to the belt, it’s important that the belt surface creates a suction effect. Tiny return radii or knife edges are required when pieces of dough are transferred to other belts.

You can easily clean the robust belt surface with appropriate belt scrapers.

Our Solution

Our durable belts with their very mechanically resistant coatings are ideal for rotary molders. They comply with food safety regulations and meet the functional requirements of the belt surface. What’s more, the belts are ideal for knife edges.

The belts (polyamide fabric or cotton coated) are FDA/EU approved, shrink resistant and can come with belt edge sealing (Smartseal).

The belt coatings are resistant to wear and tear, suitable for use with metal scrapers and have good release properties. The Z-splice can be made at a 60° angle so that the belt tracks very smoothly over the rotary molder.

Contact us if you’d like to know more

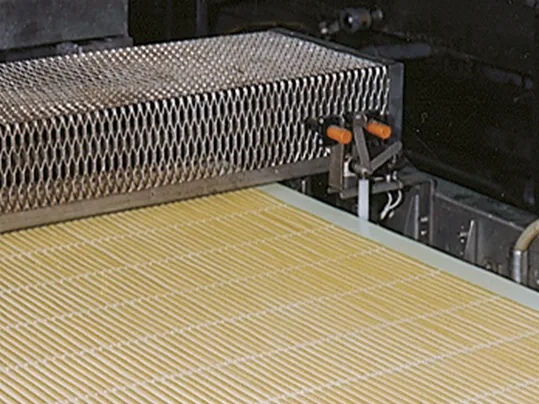

Your pieces of dough are now ready for baking. They are then sent to the oven for baking. While still hot, they are transferred from the oven belt to the out-feed belt and sent on for further processing.

Technical Requirements of the Belts

The in-feed and out-feed belts must be able to withstand high temperatures for short periods of time and have good release properties. They are constantly exposed to high temperatures in the oven itself. Small end radii are required to transfer the products. The belts must be suitable for use with foodstuffs.

Our Solution

Metal mesh or grid belts and are used in the oven itself. Heat-resistant, fabric-based conveyor belts (Siegling Transilon) or plastic modular belts (Siegling Prolink) are ideal in-feed and out-feed belts. These food-safe belts can withstand the oven’s radiant heat and run over small end radii.

For this application, fabric-based belts (Siegling Transilon) are usually made endless with a 60° Z-splice. This type of splice means that the belt tracks exceptionally smoothly over knife edges. Mechanical fasteners can also be applied.

To meet even more stringent hygiene standards, we can also apply belt edge sealing (Smartseal) to the belts as an option. Plastic modular belts (Siegling Prolink) are hygienic throughout and come with small end radii.

All the belt types used come with release friendly patterns, are easy to clean and EU- and FDA-compliant.

Contact us if you’d like to know more

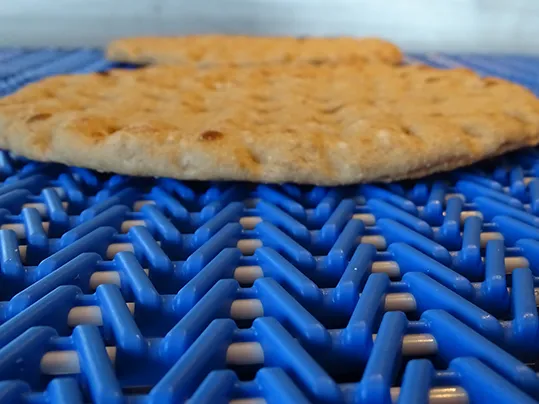

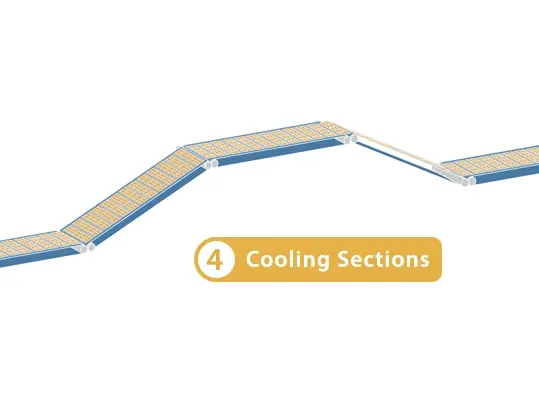

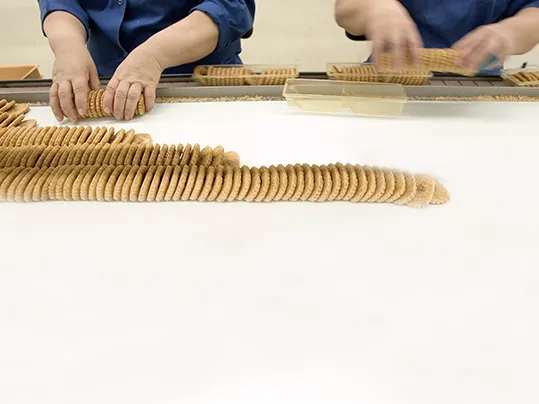

Before they are put into piles and packaged, the baked goods cool down on the cooling section and the surfaces dry. We add curved conveyors to long cooling sections.

Technical Requirements of the Belts

Conveyor belts on cooling sections must also be food safe. They also need to have abrasion-resistant surfaces and cope with curved applications exceptionally well. The belts have to track straight and withstand high temperatures.

Our Solution

You can use fabric-based conveyor belts (Siegling Transilon) and plastic modular belts (Siegling Prolink) with heat-resistant surfaces as cooling belts. Both are available as curved belts and suitable for use with foodstuffs.

Used as cooling belts, Transilon products are easy to clean, EU- and FDA-compliant and come with optional belt edge sealing (Smartseal). Curved belts with fabric tension members have enhanced fabric designs (e.g. are longitudinally and laterally flexible). They are made of several segments, which results in a good distribution of force in the belt and reliable conveying of the baked goods.

Plastic modular belts (Siegling Prolink) also track consistently straight and are available as curved belts. The belt surface’s large open area makes the baked goods cool down more quickly. The belts can also be used at very low temperatures.

Contact us if you’d like to know more

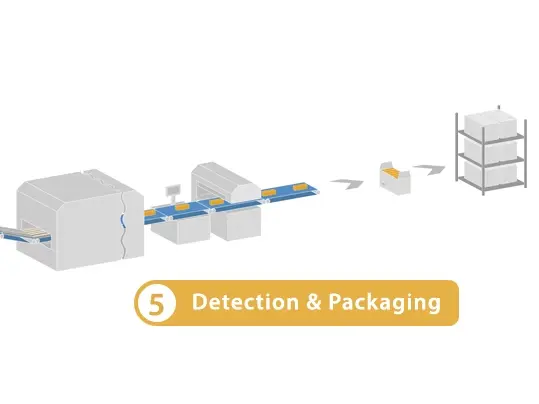

Detection methods are efficient ways of checking your products for contamination by foreign bodies. These detection processes are flexible to integrate at various points in the production process. The baked goods are then weighed and packaged to prepare them for sale. The products are usually packaged in bags or trays. Depending on the machinery and the product, the products are then labeled, wrapped and/or repackaged and deep frozen if necessary.

Technical Requirements of the Belts

The belts need to be food grade and easy to clean. Specific belt characteristics are also required, such as uniform thickness during weighing, good grip to position the product precisely and good release properties during labeling. In the case of metal detectors and x-ray equipment, the requirements depend on the application. In deep-frozen sections, the belt must not become brittle at temperatures down to -40°C.

Our Solution

Special surface characteristics make the portioning and wrapping process easier and more reliable.

Special finishes for check-weigher belts provide extremely precise splices of the same thickness.

Antistatic or non-antistatic belts are available for metal detectors, depending on requirements.

To ensure safe x-raying, belts with a high friction coefficient on the top face are used so that the equipment’s safety curtain can pass through without the products on the conveyor belt slipping.

The food-grade (Prolink) series, made of polyoxymethylene (POM) or polyethylene (PE), have exceptional service lives when products need to be deep frozen.

Contact us if you’d like to know more

Do you want tasty cookies or biscuits and ensure precise, quality-driven production from the get-go? This is where our comprehensive product portfolio comes in. We have product lines with numerous, specialist belts geared to specific process steps and your HACCP concept’s requirements.

Our conveyor belts can be spliced cleanly to guarantee virtually no markings on the bottom of products. If necessary, the splices can be made on the machinery itself. And Prolink plastic modular belts require no special tools. We can offer several splicing methods and tools for fabric-based and homogenous belts.

This careful, quality-driven approach to conveying baked goods on the production line ensures every single item is top quality without any compromises on safety.

We’d be happy to advise you and answer questions about your production line and the products we have to match.

Any questions about our products for cookie/biscuit production? Then contact us.

To the contact form