Product Range

The "pros" of Siegling Proposition:

The Siegling Proposition product range includes all common timing belt pitches for standard conveying and handling operations.

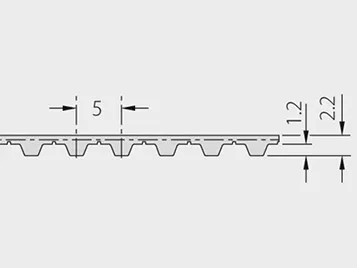

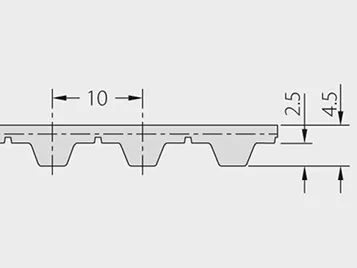

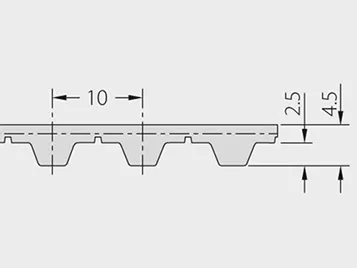

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 6 | +/- 0.5 | 0.015 | 0.012 | 10 | 16 | 25 | 230 | 110 | ||||

| 8 | + /- 0.5 | 0.019 | 0.016 | 10 | 16 | 25 | 320 | 160 | ||||

| 10 | + /- 0.5 | 0.024 | 0.020 | 10 | 16 | 30 | 25 | 310 | 430 | 150 | 210 | 310 |

| 12 | + /- 0.5 | 0.029 | 0.024 | 10 | 16 | 30 | 25 | 480 | 240 | 360 | ||

| 16 | + /- 0.5 | 0.038 | 0.032 | 10 | 16 | 30 | 25 | 460 | 610 | 230 | 300 | 490 |

| 20 | + /- 0.5 | 0.048 | 0.040 | 10 | 16 | 30 | 25 | 800 | 400 | 620 | ||

| 25 | + /- 0.5 | 0.060 | 0.050 | 10 | 16 | 30 | 25 | 830 | 980 | 410 | 490 | 800 |

| 32 | + /- 0.5 | 0.077 | 0.064 | 10 | 16 | 30 | 25 | 930 | 1200 | 460 | 600 | 1010 |

| 50 | +/- 0.5 | 0.120 | 0.100 | 10 | 16 | 30 | 25 | 1660 | 1800 | 830 | 900 | 1610 |

| 75 | + /- 0.5 | 0.180 | 0.150 | 10 | 16 | 30 | 2490 | 2410 | ||||

| 100 | + /- 0.5 | 0.240 | 0.200 | 10 | 16 | 30 | 3320 | 3220 | ||||

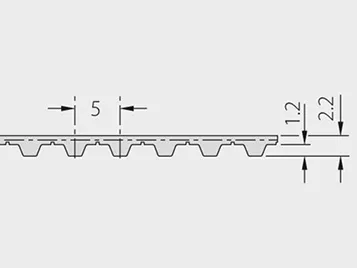

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 10 | +/- 0.5 | 0.028 | 12 | 19 | 50 | 720 | ||||||

| 12 | + /- 0.5 | 0.034 | 12 | 19 | 50 | 880 | ||||||

| 16 | + /- 0.5 | 0.045 | 12 | 19 | 50 | 1200 | ||||||

| 20 | + /- 0.5 | 0.056 | 12 | 19 | 50 | 1500 | ||||||

| 25 | + /- 0.5 | 0.070 | 12 | 19 | 50 | 1920 | ||||||

| 32 | + /- 0.5 | 0.090 | 12 | 19 | 50 | 2480 | ||||||

| 50 | +/- 0.5 | 0.140 | 12 | 19 | 50 | 3920 | ||||||

| 75 | + /- 0.5 | 0.210 | 12 | 19 | 50 | 5840 | ||||||

| 100 | + /- 0.5 | 0.280 | 12 | 19 | 50 | 7840 |

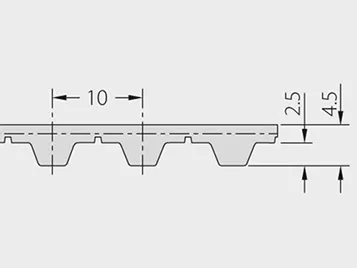

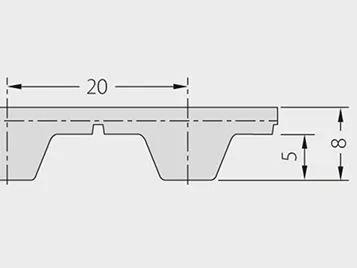

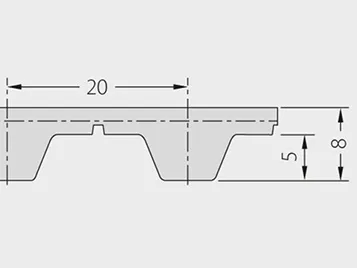

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 10 | + /- 0.5 | 0.048 | 0.040 | 12 | 38 | 60 | 50 | 700 | 350 | 700 | ||

| 12 | +/- 0.5 | 0.058 | 0.048 | 12 | 38 | 60 | 50 | 850 | 420 | 900 | ||

| 16 | + /- 0.5 | 0.077 | 0.064 | 12 | 38 | 60 | 50 | 1300 | 1000 | 650 | 500 | 1200 |

| 20 | + /- 0.5 | 0.096 | 0.080 | 12 | 38 | 60 | 50 | 1300 | 650 | 1500 | ||

| 25 | + /- 0.5 | 0.120 | 0.100 | 12 | 38 | 60 | 50 | 2200 | 1750 | 1100 | 870 | 2000 |

| 32 | + /- 0.5 | 0.154 | 0.128 | 12 | 38 | 60 | 50 | 2600 | 2350 | 1300 | 1170 | 2500 |

| 40 | + /- 0.5 | 0.192 | 0.160 | 12 | 38 | 60 | 50 | 2970 | 1480 | |||

| 50 | + /- 0.5 | 0.240 | 0.200 | 12 | 38 | 60 | 50 | 4400 | 3970 | 2200 | 1980 | 4000 |

| 75 | +/- 0.5 | 0.360 | 0.300 | 12 | 38 | 60 | 50 | 6600 | 4900 | 3300 | 2450 | 6000 |

| 100 | +/- 0.5 | 0.480 | 0.400 | 12 | 38 | 60 | 50 | 8800 | 6700 | 4400 | 3350 | 8100 |

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 16 | + /- 0.5 | 0.102 | 12 | 38 | 90 | 2160 | ||||||

| 25 | + /- 0.5 | 0.160 | 12 | 38 | 90 | 3450 | ||||||

| 32 | + /- 0.5 | 0.205 | 12 | 38 | 90 | 4530 | ||||||

| 50 | + /- 0.5 | 0.320 | 12 | 38 | 90 | 7120 | ||||||

| 75 | +/- 0.5 | 0.48 | 12 | 38 | 90 | 10800 | ||||||

| 100 | +/- 0.5 | 0.640 | 12 | 38 | 90 | 14470 | ||||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 16 | + /- 0.5 | 0.093 | 15 | 48 | 90 | 2400 | ||||||

| 20 | + /- 0.5 | 0.446 | 15 | 48 | 90 | 2840 | ||||||

| 25 | + /- 0.5 | 0.145 | 15 | 48 | 90 | 3840 | ||||||

| 50 | +/- 0.5 | 0.290 | 15 | 48 | 90 | 7920 | ||||||

| 75 | + /- 0.5 | 0.435 | 15 | 48 | 90 | 12000 | ||||||

| 100 | + /- 0.5 | 0.580 | 15 | 48 | 90 | 16080 | ||||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 16 | + /- 1.0 | 0.123 | 0.100 | 15 | 96 | 90 | 80 | 2400 | ||||

| 20 | + /- 1.0 | 0.154 | 0.130 | 15 | 96 | 90 | 80 | 3120 | ||||

| 25 | + /- 1.0 | 0.193 | 0.160 | 15 | 96 | 90 | 80 | 3360 | 2900 | 1680 | 1450 | 3840 |

| 32 | +/- 1.0 | 0.246 | 0.205 | 15 | 96 | 90 | 80 | 4320 | 3750 | 2160 | 1870 | 5040 |

| 50 | + /- 1.0 | 0.385 | 0.320 | 15 | 96 | 90 | 80 | 6720 | 5700 | 3360 | 2850 | 7920 |

| 75 | + /- 1.0 | 0.578 | 0.480 | 15 | 96 | 90 | 80 | 10080 | 8400 | 5040 | 4200 | 12000 |

| 100 | + /- 1.0 | 0.770 | 0.640 | 15 | 96 | 90 | 80 | 13440 | 11000 | 6720 | 5500 | 16080 |

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 16 | + /- 1.0 | 0.115 | 12 | 76 | 90 | 2160 | ||||||

| 20 | +/- 1.0 | 0.144 | 12 | 76 | 90 | 2590 | ||||||

| 25 | + /- 1.0 | 0.180 | 12 | 76 | 90 | 3450 | ||||||

| 32 | + /- 1.0 | 0.230 | 12 | 76 | 90 | 4530 | ||||||

| 50 | + /- 1.0 | 0.360 | 12 | 76 | 90 | 7120 | ||||||

| 75 | + /- 1.0 | 0.540 | 12 | 76 | 90 | 10800 | ||||||

| 100 | +/- 1.0 | 0.720 | 12 | 76 | 90 | 14470 | ||||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 16 | +/- 1.0 | 0.138 | 22 | 140 | 120 | 4400 | ||||||

| 20 | +/- 1.0 | 0.172 | 22 | 140 | 120 | 5500 | ||||||

| 25 | + /- 1.0 | 0.215 | 22 | 140 | 120 | 7150 | ||||||

| 32 | + /- 1.0 | 0.275 | 22 | 140 | 120 | 9350 | ||||||

| 50 | +/- 1.0 | 0.430 | 22 | 140 | 120 | 14850 | ||||||

| 75 | + /- 1.0 | 0.645 | 22 | 140 | 120 | 22000 | ||||||

| 100 | + /- 1.0 | 0.860 | 22 | 140 | 120 | 29700 | ||||||

*Lengths available from 1500 mm. up to 24.000 mm. (depending on the type)

Smaller lengths available, only in standard lengths (on request)

Most types are available with nylon fabric on each or both sides

For even more proposition see customized products

The specifications listed are based on Forbo's experience. However, our specifications and data do NOT cover all possible belt drive conditions. It is the responsibility of the belt drive system designer to ensure Forbo's belts are appropriate for a given system and application. The provided data is representative of our in-house experience and does not necessarily match product performance in industrial use. Forbo Movement Systems cannot assume any liability concerning the suitability and process ability of our products. We also cannot assume liability for process results, damages or consequential damages associated with the use of our products. Note, ultimate tensile strengths are listed for references purposes only. Ultimate tensile strength values listed above are a theoretical calculation based on average cord strength and may not represent actual tensile test results.

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | |||

| 10 | +/- 0.5 | 0.030 | 12 | 19 | 50 | 640 | 320 | 720 | ||||

| 12 | + /- 0.5 | 0.036 | 12 | 19 | 50 | 880 | ||||||

| 16 | + /- 0.5 | 0.048 | 12 | 19 | 50 | 1120 | 560 | 1200 | ||||

| 20 | + /- 0.5 | 0.060 | 12 | 19 | 50 | 1500 | ||||||

| 25 | + /- 0.5 | 0.075 | 12 | 19 | 50 | 1840 | 920 | 1920 | ||||

| 32 | +/- 0.5 | 0.096 | 12 | 19 | 50 | 2240 | 1120 | 2480 | ||||

| 50 | + /- 0.5 | 0.150 | 12 | 19 | 50 | 3680 | 1840 | 3920 | ||||

| 75 | + /- 0.5 | 0.225 | 12 | 19 | 50 | 5500 | 5840 | |||||

| 100 | + /- 0.5 | 0.300 | 12 | 19 | 50 | 7350 | 7840 | |||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] |

| Steel | Steel | Steel | Steel | Steel | ||||

| 12 | + /- 0.5 | 0.077 | 15 | 48 | 90 | 1680 | ||

| 16 | + /- 0.5 | 0.102 | 15 | 48 | 90 | 2400 | 1200 | 2400 |

| 20 | +/- 0.5 | 0.128 | 15 | 48 | 90 | 2850 | ||

| 25 | + /- 0.5 | 0.160 | 15 | 48 | 90 | 3840 | 1920 | 3840 |

| 32 | +/- 0.5 | 0.205 | 15 | 48 | 90 | 4560 | 2280 | 5040 |

| 50 | + /- 0.5 | 0.320 | 15 | 48 | 90 | 7680 | 3840 | 7920 |

| 75 | + /- 0.5 | 0.480 | 15 | 48 | 90 | 11520 | 5760 | 12000 |

| 100 | + /- 0.5 | 0.640 | 15 | 48 | 90 | 15360 | 7680 | 16080 |

| 150 | + /- 0.5 | 0.960 | 15 | 48 | 90 | 26100 | 13050 |

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | |||

| 10 | + /- 0.5 | 0.064 | 14 | 45 | 90 | 1100 | ||||||

| 12 | + /- 0.5 | 0.077 | 14 | 45 | 90 | 1350 | ||||||

| 16 | +/- 0.5 | 0.102 | 14 | 45 | 90 | 1950 | 970 | 1950 | ||||

| 20 | + /- 0.5 | 0.128 | 14 | 45 | 90 | 2340 | ||||||

| 25 | +/- 0.5 | 0.160 | 14 | 45 | 90 | 3120 | 1560 | 3120 | ||||

| 32 | + /- 0.5 | 0.205 | 14 | 45 | 90 | 3700 | 1850 | 4090 | ||||

| 50 | + /- 0.5 | 0.320 | 14 | 45 | 90 | 6200 | 3100 | 6430 | ||||

| 75 | + /- 0.5 | 0.480 | 14 | 45 | 90 | 9360 | 4680 | 9750 | ||||

| 100 | + /- 0.5 | 0.640 | 14 | 45 | 90 | 12480 | 6240 | 13060 | ||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | |||

| 10 | +/- 0.5 | 0.068 | 25 | 80 | 120 | 2760 | ||||||

| 12 | + /- 0.5 | 0.082 | 25 | 80 | 120 | 3300 | ||||||

| 16 | + /- 0.5 | 0.109 | 25 | 80 | 120 | 4400 | 1200 | 4400 | ||||

| 20 | +/- 0.5 | 0.136 | 25 | 80 | 120 | 5500 | ||||||

| 25 | + /- 0.5 | 0.170 | 25 | 80 | 120 | 6600 | 1900 | 7150 | ||||

| 32 | + /- 0.5 | 0.218 | 25 | 80 | 120 | 8800 | 2250 | 9350 | ||||

| 50 | + /- 0.5 | 0.340 | 25 | 80 | 120 | 14300 | 3800 | 14850 | ||||

| 75 | + /- 0.5 | 0.510 | 25 | 80 | 120 | 22550 | 5700 | 22000 | ||||

| 100 | + /- 0.5 | 0.680 | 25 | 80 | 120 | 30250 | 7600 | 29700 | ||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | |||

| 16 | + /- 1.0 | 0.160 | 18 | 115 | 120 | 4400 | ||||||

| 25 | + /- 1.0 | 0.250 | 18 | 115 | 120 | 6600 | 3300 | 7150 | ||||

| 32 | + /- 1.0 | 0.320 | 18 | 115 | 120 | 8800 | 4400 | 9350 | ||||

| 50 | + /- 1.0 | 0.500 | 18 | 115 | 120 | 13200 | 6600 | 14850 | ||||

| 75 | +/- 1.0 | 0.750 | 18 | 115 | 120 | 19800 | 9900 | 22000 | ||||

| 100 | + /- 1.0 | 1.000 | 18 | 115 | 120 | 26400 | 13200 | 29700 | ||||

| 150 | + /- 1.0 | 1.500 | 18 | 115 | 120 | 39600 | 19800 | |||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 25 | + /- 1.0 | 0.278 | 22 | 140 | 170 | 8000 | 8000 | |||||

| 32 | + /- 1.0 | 0.355 | 22 | 140 | 170 | 10000 | 10000 | |||||

| 50 | + /- 1.0 | 0.555 | 22 | 140 | 170 | 17000 | 16000 | |||||

| 75 | + /- 1.0 | 0.833 | 22 | 140 | 170 | 26000 | 24000 | |||||

| 100 | + /- 1.0 | 1.110 | 22 | 140 | 170 | 35000 | 33000 | undefined | ||||

| 150 | + /- 1.0 | 1.665 | 22 | 140 | 170 | 53000 | ||||||

*Lengths available from 1500 mm. up to 24,000 mm. (depending on the type)

Smaller lengths available (on request)

Most types are available with nylon fabric on each or both sides

For even more proposition see customized products

The specifications listed are based on Forbo's experience. However, our specifications and data do NOT cover all possible belt drive conditions. It is the responsibility of the belt drive system designer to ensure Forbo's belts are appropriate for a given system and application. The provided data is representative of our in-house experience and does not necessarily match product performance in industrial use. Forbo Movement Systems cannot assume any liability concerning the suitability and process ability of our products. We also cannot assume liability for process results, damages or consequential damages associated with the use of our products. Note, ultimate tensile strengths are listed for references purposes only. Ultimate tensile strength values listed above are a theoretical calculation based on average cord strength and may not represent actual tensile test results.

| Width [mm] | Width [inch] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] |

| Kevlar | Kevlar | Kevlar | Kevlar | |||||

| 6.4 | 0.25 | + /- 0.5 | 0.012 | 10 | 16 | 25 | 250 | 120 |

| 7.9 | 0.31 | + /- 0.5 | 0.014 | 10 | 16 | 25 | 320 | 160 |

| 9.5 | 0.37 | + /- 0.5 | 0.017 | 10 | 16 | 25 | 410 | 200 |

| 12.7 | 0.5 | +/- 0.5 | 0.023 | 10 | 16 | 25 | 500 | 250 |

| 19.1 | 0.8 | + /- 0.5 | 0.034 | 10 | 16 | 25 | 780 | 390 |

| 25.4 | 1.0 | + /- 0.5 | 0.046 | 10 | 16 | 25 | 1000 | 500 |

| Width [mm] | Width [inch] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 9.5 | 0.37 | +/- 0.5 | 0.030 | 12 | 36 | 55 | 620 | 310 | |||||

| 12.7 | 0.5 | +/- 0.5 | 0.041 | 12 | 36 | 55 | 830 | 410 | |||||

| 19.1 | 0.8 | + /- 0.5 | 0.074 | 0.061 | 12 | 36 | 60 | 55 | 1600 | 1250 | 800 | 620 | |

| 25.4 | 1.0 | +/- 0.5 | 0.099 | 0.081 | 12 | 36 | 60 | 55 | 2200 | 1660 | 1100 | 830 | |

| 38.1 | 1.5 | + /- 0.5 | 0.149 | 0.122 | 12 | 36 | 60 | 55 | 3200 | 2480 | 1600 | 1240 | |

| 50.8 | 2.0 | + /- 0.5 | 0.198 | 0.163 | 12 | 36 | 60 | 55 | 4400 | 3320 | 2200 | 1660 | |

| 76.2 | 3.0 | + /- 0.5 | 0.297 | 0.244 | 12 | 36 | 60 | 55 | 6600 | 4960 | 3300 | 2480 | |

| 101.6 | 4.0 | +/- 0.5 | 0.396 | 0.325 | 12 | 36 | 60 | 55 | 8800 | 6640 | 4400 | 3320 | |

| Width [mm] | Width [inch] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | |||||

| 12.7 | 0.5 | + /- 0.5 | 0.057 | 0.044 | 14 | 56 | 60 | 65 | 1000 | 830 | 500 | 410 | 1000 |

| 19.1 | 0.75 | +/-0.5 | 0.086 | 0.067 | 14 | 56 | 60 | 55 | 1600 | 1250 | 800 | 620 | 1500 |

| 25.4 | 1.0 | +/-0.5 | 0.114 | 0.089 | 14 | 56 | 60 | 55 | 2200 | 1660 | 1100 | 830 | 2000 |

| 38.1 | 1.5 | +/-0.5 | 0.171 | 0.133 | 14 | 56 | 60 | 55 | 3200 | 2480 | 1600 | 1240 | 3000 |

| 50.8 | 2.0 | +/-0.5 | 0.229 | 0.178 | 14 | 56 | 60 | 55 | 4400 | 3320 | 2200 | 1660 | 4000 |

| 76.2 | 3.0 | +/-0.5 | 0.343 | 0.267 | 14 | 56 | 60 | 55 | 6600 | 4900 | 3300 | 2450 | 6000 |

| 101.6 | 0.5 | +/-0.5 | 0.457 | 0.356 | 14 | 56 | 60 | 55 | 8800 | 6300 | 4400 | 3150 | 8100 |

| Width [mm] | Width [inch] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Truly endless belts* F perm [N] | |||

| Steel | Kevlar | Steel | Kevlar | Steel | ||||||

| 12.7 | 0.5 | + /- 0.5 | 0.066 | 12 | 49 | 90 | 1720 | |||

| 19.1 | 0.75 | + /- 0.5 | 0.099 | 12 | 49 | 90 | 2590 | |||

| 25.4 | 1 | + /- 0.5 | 0.132 | 12 | 49 | 90 | 3450 | |||

| 38.1 | 1.5 | + /- 0.5 | 0.198 | 12 | 49 | 90 | 5400 | |||

| 50.8 | 2 | + /- 0.5 | 0.265 | 12 | 49 | 90 | 7120 | |||

| 76.2 | 3 | + /- 0.5 | 0.396 | 12 | 49 | 90 | 10800 | |||

| 101.6 | 4 | + /- 0.5 | 0.528 | 12 | 49 | 90 | 14470 | |||

| Width [mm] | Width [inch] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Truly endless belts* F perm [N] | |||

| Steel | Kevlar | Steel | Kevlar | Steel | ||||||

| 12.7 | 0.5 | + /- 0.5 | 0.070 | 15 | 61 | 90 | 1920 | |||

| 19.1 | 0.75 | + /- 0.5 | 0.105 | 15 | 61 | 90 | 2880 | |||

| 25.4 | 1 | + /- 0.5 | 0.140 | 15 | 61 | 90 | 3840 | |||

| 38.1 | 1.5 | + /- 0.5 | 0.210 | 15 | 61 | 90 | 6000 | |||

| 50.8 | 2 | + /- 0.5 | 0.280 | 15 | 61 | 90 | 7920 | |||

| 76.2 | 3 | + /- 0.5 | 0.420 | 15 | 61 | 90 | 12000 | |||

| 101.6 | 4 | + /- 0.5 | 0.560 | 15 | 61 | 90 | 16080 | |||

| Width [mm] | Width [inch] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | |||||

| 25.4 | 1.0 | + /- 1.0 | 0.254 | 18 | 127 | 150 | 3360 | 1680 | ||||

| 50.8 | 2.0 | + /- 1.0 | 0.508 | 18 | 127 | 150 | 6720 | 3360 | ||||

| 76.2 | 3.0 | + /- 1.0 | 0.762 | 18 | 127 | 150 | 10080 | 5040 | ||||

| 101.6 | 4.0 | + /- 1.0 | 1.016 | 18 | 127 | 150 | 13440 | 6720 | ||||

*Lengths available from 1500 mm. up to 24,000 mm. (depending on the type)

Smaller lengths available (on request)

Most types are available with nylon fabric on each or both sides

For even more proposition see customized products

The specifications listed are based on Forbo's experience. However, our specifications and data do NOT cover all possible belt drive conditions. It is the responsibility of the belt drive system designer to ensure Forbo's belts are appropriate for a given system and application. The provided data is representative of our in-house experience and does not necessarily match product performance in industrial use. Forbo Movement Systems cannot assume any liability concerning the suitability and process ability of our products. We also cannot assume liability for process results, damages or consequential damages associated with the use of our products. Note, ultimate tensile strengths are listed for references purposes only. Ultimate tensile strength values listed above are a theoretical calculation based on average cord strength and may not represent actual tensile test results.

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm[N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 10 | + /- 0.5 | 0.048 | 13 | 21 | 50 | 640 | 320 | 720 | ||||

| 12 | + /- 0.5 | 0.058 | 13 | 21 | 50 | 880 | ||||||

| 15 | + /- 0.5 | 0.072 | 13 | 21 | 50 | 1120 | 560 | 1120 | ||||

| 20 | + /- 0.5 | 0.096 | 13 | 21 | 50 | 1500 | ||||||

| 25 | + /- 0.5 | 0.120 | 13 | 21 | 50 | 1840 | 920 | 1920 | ||||

| 32 | + /- 0.5 | 0.154 | 13 | 21 | 50 | 2480 | ||||||

| 50 | + /- 0.5 | 0.240 | 13 | 21 | 50 | 3680 | 1340 | 3920 | ||||

| 75 | + /- 0.5 | 0.360 | 13 | 21 | 50 | 5840 | ||||||

| 100 | + /- 0.5 | 0.480 | 13 | 21 | 50 | 7840 | ||||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 10 | + /- 0.5 | 0.069 | 18 | 46 | 90 | 1200 | 600 | |||||

| 15 | + /- 0.5 | 0.104 | 18 | 46 | 90 | 1920 | 960 | |||||

| 20 | + /- 0.5 | 0.138 | 18 | 46 | 90 | 2880 | 1440 | 3120 | ||||

| 25 | + /- 0.5 | 0.173 | 18 | 46 | 90 | 3840 | 1920 | 3840 | ||||

| 30 | + /- 0.5 | 0.207 | 18 | 46 | 90 | 4800 | 2400 | 4800 | ||||

| 50 | + /- 0.5 | 0.345 | 18 | 46 | 90 | 7680 | 3840 | 7920 | ||||

| 85 | + /- 0.5 | 0.587 | 18 | 46 | 90 | 14640 | 7320 | 13440 | ||||

| 100 | + /- 0.5 | 0.690 | 18 | 46 | 90 | 15360 | ||||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 20 | + /- 0.5 | 0.130 | 16 | 41 | 90 | 2590 | ||||||

| 25 | + /- 0.5 | 0.163 | 16 | 41 | 90 | 3450 | ||||||

| 30 | + /- 0.5 | 0.195 | 16 | 41 | 90 | 4100 | ||||||

| 50 | + /- 0.5 | 0.325 | 16 | 41 | 90 | 7120 | ||||||

| 85 | + /- 0.5 | 0.553 | 16 | 41 | 90 | 12090 | ||||||

| 100 | + /- 0.5 | 0.650 | 16 | 41 | 90 | 14470 | ||||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Truly endless belts* F perm [N] | ||||||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | ||||

| 25 | + /- 1.0 | 0.275 | 25 | 111 | 120 | 6600 | 3300 | 7150 | ||||

| 40 | + /- 1.0 | 0.440 | 25 | 111 | 120 | 11000 | 5500 | 115500 | ||||

| 55 | + /- 1.0 | 0.605 | 25 | 111 | 120 | 15950 | 7970 | 15950 | ||||

| 85 | + /- 1.0 | 0.935 | 25 | 111 | 120 | 25300 | 12650 | 24750 | ||||

| 115 | + /- 1.0 | 1.265 | 25 | 111 | 120 | 35200 | 17600 | |||||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | (min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | ||

| Steel | Steel | Steel | |||||

| 55 | + /- 1.0 | 0.660 | 34 | 152 | 170 | 19000 | |

| 85 | + /- 1.0 | 1.020 | 34 | 152 | 170 | 29000 | |

| 115 | + /- 1.0 | 1.380 | 34 | 152 | 170 | 40000 | |

| 150 | + /- 1.0 | 1.800 | 34 | 152 | 170 | 53000 | |

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | |||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | ||||

| 55 | + /- 1.0 | 0.743 | 38 | 174 | 180 | 23680 | |||

| 85 | + /- 1.0 | 1.148 | 38 | 174 | 180 | 38480 | |||

| 115 | + /- 1.0 | 1.553 | 38 | 174 | 180 | 51800 | |||

| 150 | + /- 1.0 | 2.025 | 38 | 174 | 180 | 68080 | |||

| Width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | z(min) minimum number of teeth | d(min) approx. [mm] | d(min) approx. [mm] tensioning roller on reverse side of belt | Open belts F perm [N] | Endless welded belts F perm [N] | Truly endless belts* F perm [N] | ||||

| | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | Steel | |||

| 15 | + /- 0.5 | 0.096 | 18 | 46 | 90 | 1920 | 960 | |||||

| 20 | + /- 0.5 | 0.128 | 18 | 46 | 90 | 2880 | 1440 | |||||

| 25 | + /- 0.5 | 0.160 | 18 | 46 | 90 | 3840 | 1920 | |||||

| 30 | + /- 0.5 | 0.192 | 18 | 46 | 90 | 4800 | 2400 | |||||

| 50 | + /- 0.5 | 0.320 | 18 | 46 | 90 | 7680 | 3840 | |||||

| 85 | + /- 0.5 | 0.544 | 18 | 46 | 90 | 14640 | 7320 | |||||

*Lengths available from 1500 mm. up to 24,000 mm. (depending on the type)

Smaller lengths available (on request)

Most types are available with nylon fabric on each or both sides

For even more proposition see customized products

The specifications listed are based on Forbo's experience. However, our specifications and data do NOT cover all possible belt drive conditions. It is the responsibility of the belt drive system designer to ensure Forbo's belts are appropriate for a given system and application. The provided data is representative of our in-house experience and does not necessarily match product performance in industrial use. Forbo Movement Systems cannot assume any liability concerning the suitability and process ability of our products. We also cannot assume liability for process results, damages or consequential damages associated with the use of our products. Note, ultimate tensile strengths are listed for references purposes only. Ultimate tensile strength values listed above are a theoretical calculation based on average cord strength and may not represent actual tensile test results.

Endless welded belts Min. width [mm] Max. width [mm] Width tolerance [mm] Weight, approx. [kg/m2/cm2] zmin minimum number of teeth dmin approx. [mm] dmin approx. [mm] tensioning roller on reverse side of belt F perm [N/25 mm.] Min. production length [mm] Kevlar Kevlar Kevlar WT 10 150 450 1/-2 0.039 14 45 80 315 1100 WH 152.4 457.2 1/-2 0.033 14 56.64 80 315 1104.9

Available with nylon fabric in each or both sides

For even more proposition see customized products

The specifications listed are based on Forbo's experience. However, our specifications and data do NOT cover all possible belt drive conditions. It is the responsibility of the belt drive system designer to ensure Forbo's belts are appropriate for a given system and application. The provided data is representative of our in-house experience and does not necessarily match product performance in industrial use. Forbo Movement Systems cannot assume any liability concerning the suitability and process ability of our products. We also cannot assume liability for process results, damages or consequential damages associated with the use of our products. Note, ultimate tensile strengths are listed for references purposes only. Ultimate tensile strength values listed above are a theoretical calculation based on average cord strength and may not represent actual tensile test results.

| Standard width [mm] | Width tolerance [mm] | Weight. approx. [kg/m2] | Minimum pulley diameter [mm] | Min. tension idler diameter [mm] | Open belts F perm [N] | Endless welded belts | |||

| Steel | Kevlar | Steel | Kevlar | Steel | Kevlar | ||||

| 15 | + /- 0.5 | 0.068 | 50 | 90 | 2160 | ||||

| 25 | + /- 0.5 | 0.113 | 50 | 90 | 3840 | ||||

| 30 | + /- 0.5 | 0.135 | 50 | 90 | 4320 | ||||

| 40 | + /- 0.5 | 0.180 | 50 | 90 | 6400 | ||||

| 50 | + /- 0.5 | 0.225 | 50 | 90 | 7600 | ||||

| 75 | + /- 0.5 | 0.338 | 50 | 90 | 11520 | ||||

| 100 | + /- 0.5 | 0.450 | 50 | 90 | 15360 | ||||

Also available are the thicknesses 3.2 mm, 3.8 mm and 4.8 mm. Various types can be provided with tension members of steel, kevlar and stainless steel, in some cases reinforced and/or high flexible.

* other widths on request

For even more proposition see customized products

The specifications listed are based on Forbo's experience. However, our specifications and data do NOT cover all possible belt drive conditions. It is the responsibility of the belt drive system designer to ensure Forbo's belts are appropriate for a given system and application. The provided data is representative of our in-house experience and does not necessarily match product performance in industrial use. Forbo Movement Systems cannot assume any liability concerning the suitability and process ability of our products. We also cannot assume liability for process results, damages or consequential damages associated with the use of our products. Note, ultimate tensile strengths are listed for references purposes only. Ultimate tensile strength values listed above are a theoretical calculation based on average cord strength and may not represent actual tensile test results.