eurocol

813 EUROFLOOR FORCE FIBRE

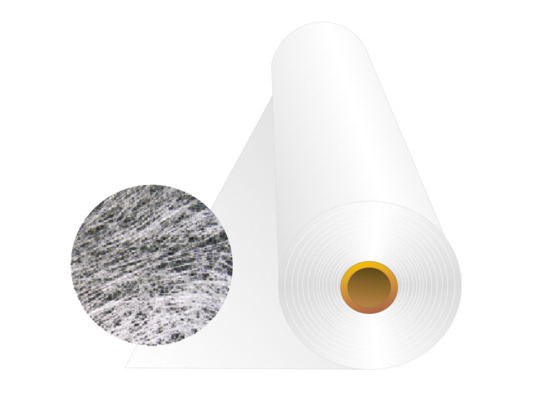

Reinforcing scrims, for load distribution, before levelling work, the fibre scrims are separated into individual fibres and which additionally reinforce the levelling compound.