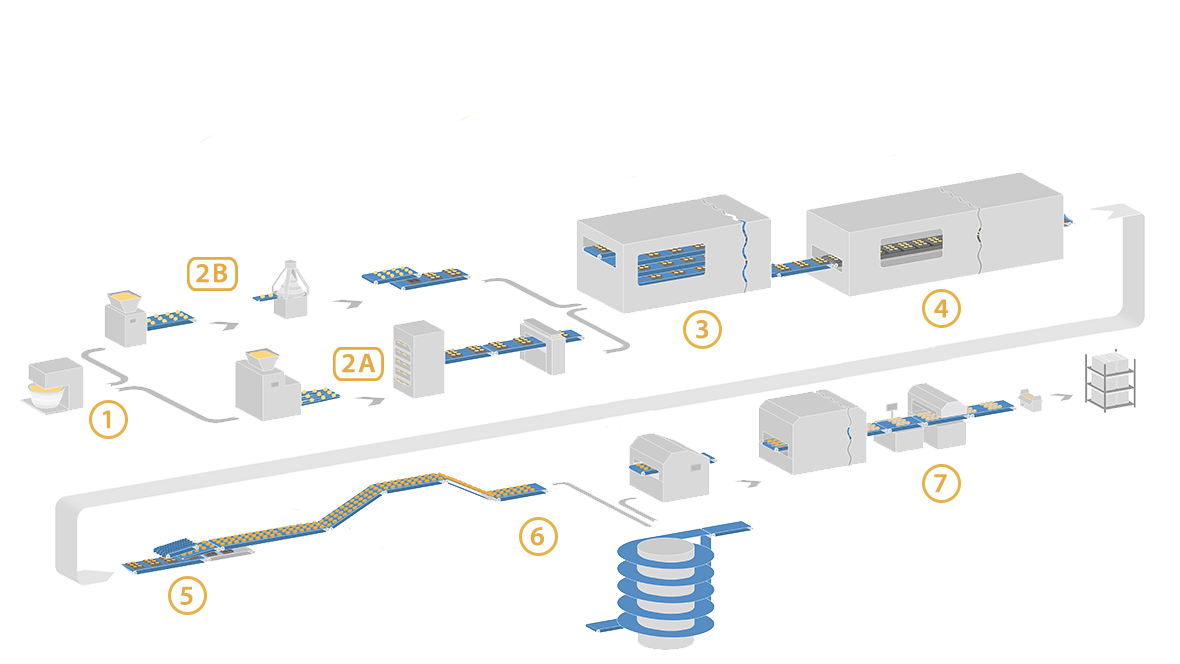

Bread & Buns Production Process

Baking bread, buns and bread rolls is an age-old craft. It’s a combination of science and an art form. The first step is to combine the ingredients and form the loaves, buns and bread rolls.

After careful proofing, the heat-resistant conveyor belts take the pieces of dough to the oven. After baking, depanners remove the pieces of dough from the molds. They then cool down in the cooling section. The bakers then check and package the loaves, buns and bread rolls. Conveyor belts play a key role in each step of the production process. To ensure good quality products, these need to be robust and flexible to handle the demands of the baking process.

From forming to packaging, we can recommend the best processing belts for your dough and processes.

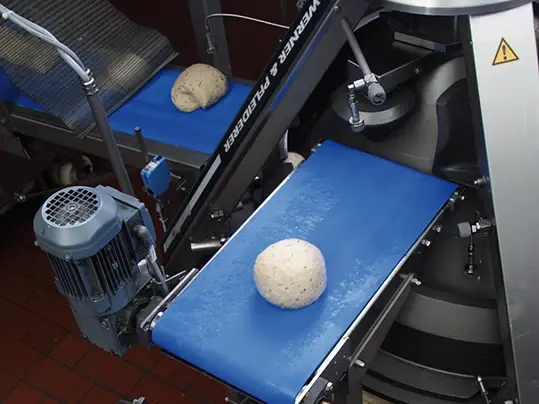

Once the dough is mixed, hoppers feed it into the production process. These hoppers can be lined with hygienic belting material. Various forming processes then follow.

Technical Requirements of the Belts

Between the production stages, these food-grade belts with their good grip and release properties are perfect for conveying dough. Depending on the conveying angle, patterned belts are a good choice. Tight return radii at the end of the conveyor facilitate dough release.

Our Solution

We offer conventional fabric-based and homogenous belt types for dough feed. These comply with the required food-safety specifications. A range of coating materials such as PU or polyolefin guarantee high standards of hygiene, excellent grip, and release properties.

They are MHLW-, EU- and FDA-compliant and easy to clean. We’d be happy to seal the belt edges (with Smartseal). Or our special Frayfree design guarantees that even unsealed belt edges won’t fray.

Contact us if you’d like to know more

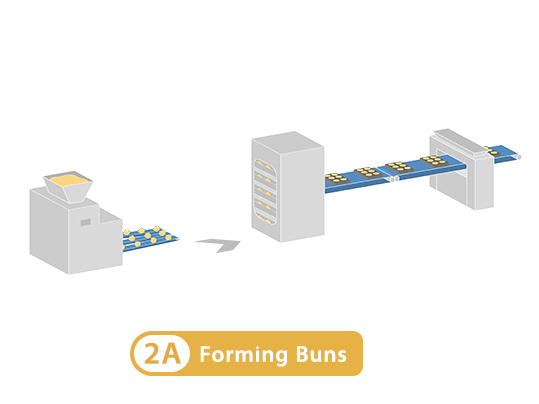

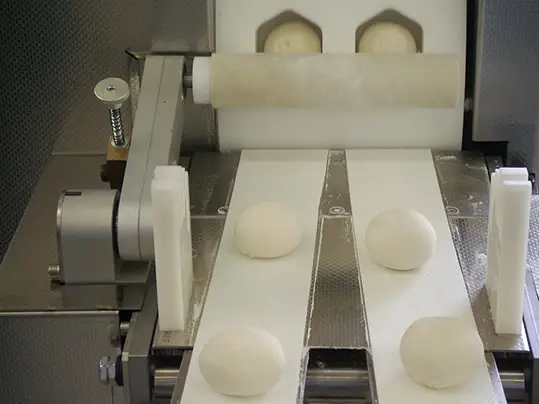

Now your bread rolls/buns are given their shape. First of all, they’re divided into portions before various processes form them into the shape desired. This is frequently performed by a process known as rounding. After forming, the pieces of dough are sent to the intermediate proofer and ingredients can be sprinkled on them if desired.

Technical Requirements of the Belts

For dough forming, the conveyor belts must have exceptionally good grip and release properties, outstanding positioning accuracy and be suitable for use with foodstuffs. Our forming belts excel at rounding. Our spreading belts are troughable, elastic and have excellent release properties, even if little flour is used.

Mold-resistant belts that can withstand the special ambient conditions (40°C, high humidity) are particularly important for the intermediate proofer.

Our Solution

We have several belt types suitable for bread-roll/bun-forming: Depending on your forming, conveying and intermediate proofing requirements, our fabric-based, elastic, and homogenous belts, or plastic modular belts, have the required grip and food properties.

For rounding, we recommend our robust, two-ply urethane types, which can be coated with cotton.

As spreading belts, elastic urethane ones are the hygienic alternative to conventional cotton belts.

TPU belts with and without fabric linings, or plastic modular belts (in spiral towers) can be used for the intermediate proofer.

If desired, we can add belt edge sealing (Smartseal) to many belts. And even if belt edges are not sealed, we can minimize fraying thanks to a special belt design (Frayfree).

These belts’ good release properties minimize the need for flour as a release agent. The easy-to-clean belts are also EU- and FDA-compliant.

CONTACT US IF YOU’D LIKE TO KNOW MORE

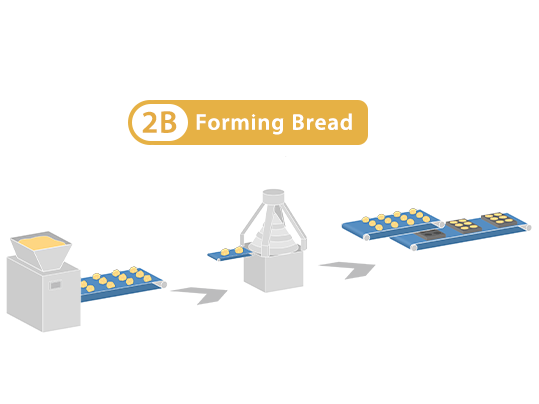

Rounding or forming with belts in opposing directions lend the pieces of dough their typical loaf shape. Some of these are processed further in molds afterward.

Technical Requirements of the Belts

For rounding or forming, you need food-grade conveyor belts with quite high belt tension. Even when some flour is used, they must have very good release properties.

Small end radii facilitate transfer of the pieces of dough to subsequent belt sections.

Our Solution

We want to ensure that you end up with a loaf that meets your requirements. Consequently, we can offer you multiple fabric-based, elastic, and homogenous belts for the processing and conveying tasks you need. These belts are tailored to your conveying, food-safety and forming requirements.

The belt types are FDA- and EU-approved. If desired, we can add belt edge sealing (Smartseal) to your belts. We can also offer you an optional, special belt design (Frayfree) that minimizes fraying of unsealed belt edges. The wear-proof belt coatings have special surfaces. Many of the belts are ideal for knife edges.

CONTACT US IF YOU’D LIKE TO KNOW MORE

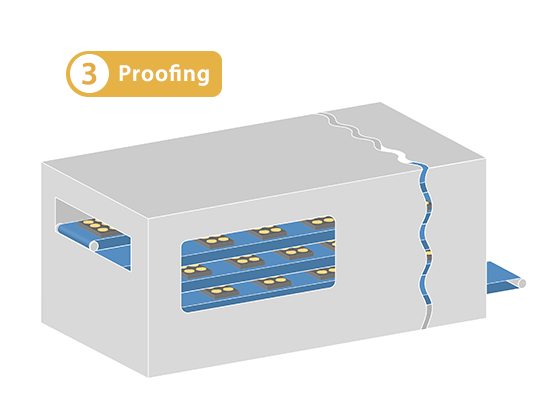

Before baking, all sourdough loaves are left to proof. During this period, any stretching or vibrating of the dough must be avoided. As this process takes quite a lot of time, slow, cascading conveyors or spiral towers are used. Discontinuous proofing processes without conveyor belts are also used.

Technical Requirements of the Belts

Due to the exceptional ambient conditions (approx. 40°C, high humidity), the risk of mold growing increases during proofing. Alongside the need for food-grade belts with good grip and release properties, mold resistance is the key requirement at this stage of production.

Our Solution

Forbo Movement Systems offers numerous fabric-based, homogenous belts and plastic modular ones for the proofing process. The belts combine the requisite properties for foodstuffs and grip with the requirements of the proofing process.

For cascading conveyors, fabric-based belts (Siegling Transilon) with belt edge sealing (Fullseal), as well as homogenous TPU belts (Siegling Fullsan), provide the protection from mold growth required. In spiral towers, elastic modular belts with a large open area (Siegling Prolink) with little contact between the product and belt surface are primarily used. All belt types are easy to clean and EU- and FDA-compliant.

Contact us if you’d like to know more

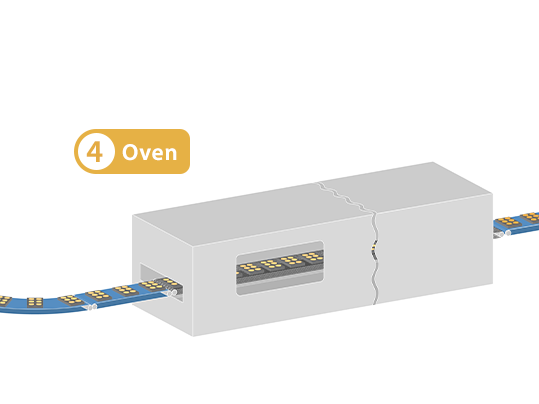

After proofing, the pieces of dough go straight into the oven. They are baked until golden brown. While the loaves, buns and bread rolls are still hot, an out-feed belt takes them off for further processing.

Technical Requirements of the Belts

In-feed and out-feed belts need to be able to withstand extreme temperatures for short periods of time. At this step in the process, good release properties and belts with tight return radii when the product is transferred are a must.

Our Solution

Metal mesh or grid belts are used in the oven itself, but these are not part of our product range. Our fabric-based conveyor belts (Siegling Transilon) or plastic modular belts (Siegling Prolink) are ideal in-feed and out-feed belts. These food-safe belts can withstand the oven’s radiant heat and run over small end radii.

For this application, fabric-based belts (Siegling Transilon) are usually made endless with a 60° Z-splice. This type of splice allows exceptionally smooth belt tracking over knife edges. Mechanical fasteners can also be applied.

If a high standard of hygiene is desired, we can add belt edge sealing (Smartseal) to you belts. In addition to offering hygienic surfaces through and through, plastic modular belts (Siegling Prolink) also come with small end radii.

All the belt types used come with release friendly patterns, are easy to clean and EU- and FDA-compliant.

Contact us if you’d like to know more

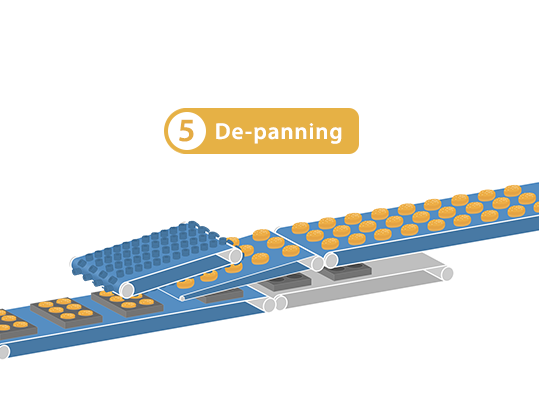

Dough in molds needs to be removed after baking. In automated processes, this step is carried out by a vacuum belt above the conveyor. Suction cups on the belt attach themselves to the loaves and lift them out of the mold.

At the end of the vacuum belt, the suction cups place the shaped loaves on the next belt.

Technical Requirements of the Belts

Despite relatively big vacuum openings, the belts must be capable of withstanding the tensile load from the loaves hanging off them. The out-feed belt must have an open area so that the loaves can cool down well.

Our Solution

Our fabric-based conveyor belts (Siegling Transilon) are ideal as vacuum belts and have special perforations for this application. You can attach the appropriate suction cups to these perforations.

For onward conveying, plastic modular belts (Siegling Prolink) with open areas of up to 57% are ideal for cooling the loaves down quickly and in a controlled manner.

All belt types are easy to clean and EU- and FDA-compliant.

CONTACT US IF YOU’D LIKE TO KNOW MORE

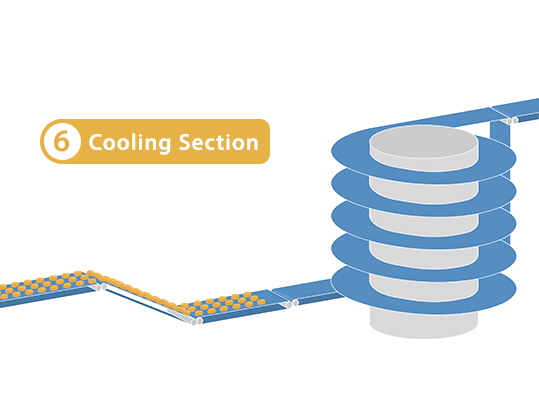

Before they are put into piles and packaged, the baked goods cool down on the cooling section and the surfaces dry. Curved conveyors are often added to the relatively long cooling sections.

Technical Requirements of the Belts

All belts must be suitable for use with foodstuffs. They need to have relatively heat- and abrasion-resistant surfaces and be able to cope with curved applications if necessary.

Our Solution

You can use our fabric-based conveyor belts (Siegling Transilon) as heat-resistant cooling belts. These are easy to clean, EU- and FDA-compliant and come with optional belt edge sealing (Smartseal).

Curved belts with fabric tension members have enhanced fabric designs (e.g. are longitudinally and laterally flexible). They are made of several segments, resulting in a good distribution of force in the belt.

Our plastic modular belts (Siegling Prolink) with heat-resistant surfaces are also ideal as cooling belts. They can also be supplied for straight and curved sections. Belt types with large open areas improve cooling of the baked goods and are also excellent for use in very low temperatures.

CONTACT US IF YOU’D LIKE TO KNOW MORE

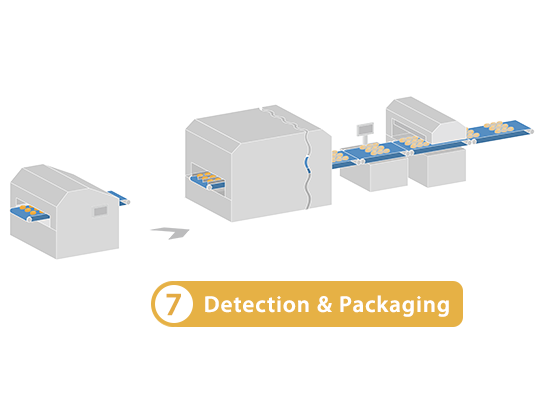

Before your loaves, buns and bread rolls are cut, packaged and sealed, a range of methods is used to spot any foreign bodies in the products. These detection processes can be integrated at various points in the production process.

If everything’s in order, products are weighed and packaged appropriately for sale. The products are usually packaged in bags or trays and then wrapped. Depending on the machinery and the product, the products are then labeled, wrapped and/or repackaged and deep frozen if necessary.

Belt Specifications Required

The belts need to be suitable for use with foodstuffs and easy to clean. Specific belt characteristics are also required, such as uniform thickness during the weighing process, good grip in order to position the product precisely and good release properties during the labelling process. In the case of metal detectors and X-ray equipment, the requirements depend on the application. In deep-frozen sections, the belt must not become brittle at temperatures down to -40°C.

Our Solution

Special surface characteristics make the portioning and wrapping process easier and more reliable. Special finishes for check-weigher belts provide extremely precise splices of the same thickness. Antistatic or non-antistatic belts are available for metal detectors, depending on requirements. To ensure safe x-raying, belts with a high friction coefficient on the top face are used so that the equipment’s safety curtain can pass through without the products on the conveyor belt slipping.

The food-grade (Prolink) series, made of polyoxymethylene (POM) from series 13 for instance, or polyethylene (PE), from series 14 for example, have exceptional service lives when products need to be deep frozen.

Contact us if you’d like to know more

Making bread, buns and bread rolls is a complex series of steps, where precision and quality are a must. The various belt types don’t just guarantee perfect conveying and processing of the dough. They also play a key role in the quality of the final product. Each belt fulfills a specific function – from mixing to forming to packaging.

Our conveyor belts have perfect splices and guarantee that the bottom of the product is flawless. If required, we can make these splices on your machinery. We don’t need any special tools for our Prolink plastic modular belts. We use a range of splicing methods and tools for fabric-based and homogenous belts.

Our food-grade belts guarantee that your products are top quality and comply with stringent safety standards.

Reach out to us if you have any questions about your production process and our products.

Any questions about our products for bread, bun and bread roll production? Then contact us.

To the contact form