Secondary Processing

Filter and cigarette manufacture is carried out in secondary processing.

The TT suffix (TT = Tobacco Type) is added to the name of all Siegling Transilon belt types suitable for the tobacco industry. All tobacco types are food safe and pyrolysis compliant. Only conveyor belts made wholly of polyolefin, polyester or silicone fulfil the stringent requirements the tobacco industry places.

The tobacco industry demands the usage of conveyor belts that don’t form any products like nitrogen, sulphur, chlorine or fluorine that are hazardous to health during combustion. This is verified by pyrolytic cleavage, i.e. by burning the belt material at 800°C in the absence of oxygen. The mass fractions of the combustion products are then identified.

The FDA's and EU’s plastics regulations on direct contact with food protect consumers from substances which present a health risk. When conveying tobacco, unwanted substances could be transferred to the tobacco. Belt manufacturers don’t just have to comply with the regulations, but also need to indicate compliance on conformity declarations. Which we do of course provide for all belts in our tobacco range.

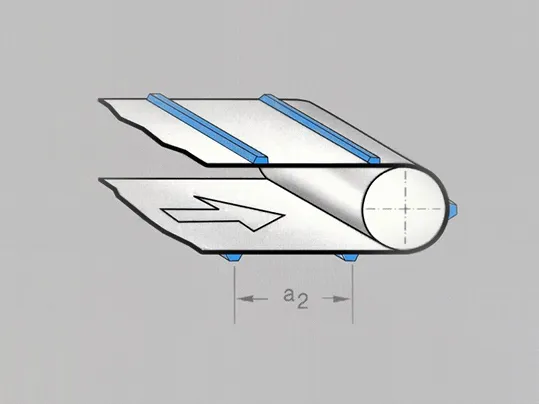

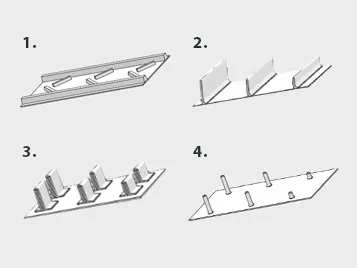

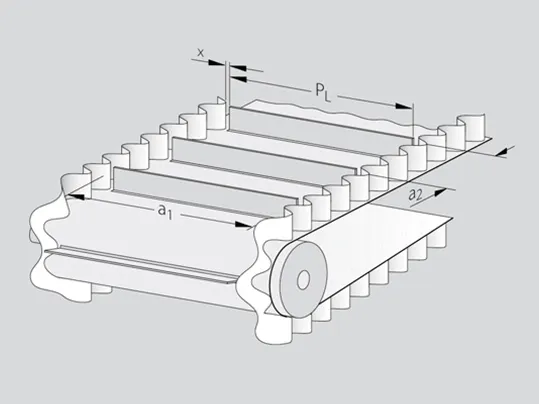

Conveyor belts fitted with profiles for inclined conveying at a steep gradient are an alternative to metal rakes and therefore save costly set-up times. Polyester profiles are available in several shapes and dimensions and some of them can be supplied as roll material.

Ref. No. 318 | Issue 06/20

(PDF | EN)

1. K-profiles

(10–17 mm height)

2. LB profiles/T profiles

(20–60 mm/10 mm height)

3. Loop profiles

(20–100 mm height)

4. Rake profiles

(max. 80 mm height)

A sidewall range, especially for the tobacco industry’s requirements, is available for inclined and steep tobacco conveying. There is a choice of polyester sidewalls, 40 mm to 80 mm in height.

Ref. No. 120 | Issue 08/12

(PDF | EN)

Ref. No. 318 | Issue 06/20

(PDF | EN)

Smartseal belt edge sealing prevents oil, grease, water and therefore bacteria from entering the belt. Fluff protruding at the belt edges is reliably prevented. This sealing method is successfully used to handle the exacting demands placed on the hygiene of conveyor belts made of synthetic materials and with fabric tension members.

Ref. No 247 | Issue 03/17

(PDF | EN)

Amp Miser™ conveyor belts are an impressive example of energy saving. In comparison with standard belts, these conveyor belts and their special underside fabric qualities (patented) have a radically lower friction coefficient to steel, so that energy savings of up to 40% are achievable.

Ref. No. 238

(PDF | EN)