Packaging

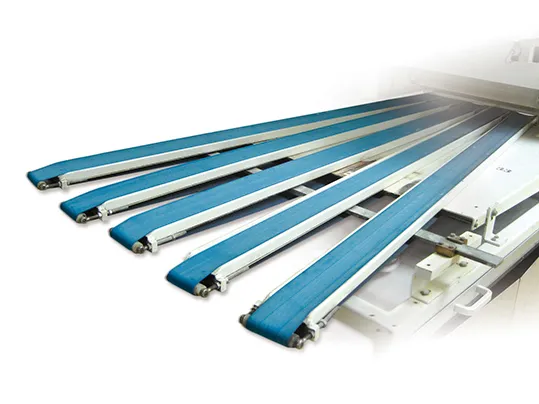

In addition to traditional food packaging machinery, buffer systems, check-weighers, robots (vision systems), or box conveying systems are also part of the packaging area.

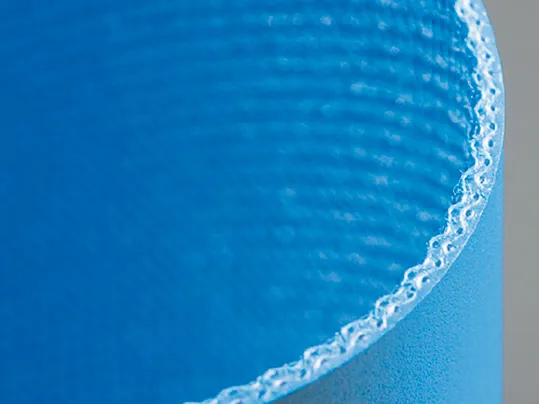

Due to the special design of Forbo’s Frayfree belts, virtually no fluff forms on the edges of the belt. A special type of fabric and weave as well as an enhanced filament length, ensures that no problems are caused by the unsealed belt edges. The versatile product range is suitable for a wide variety of applications and perfectly fulfils the stringent demands of the food industry.

Ref. No. 246

PDF | EN | 167 KB

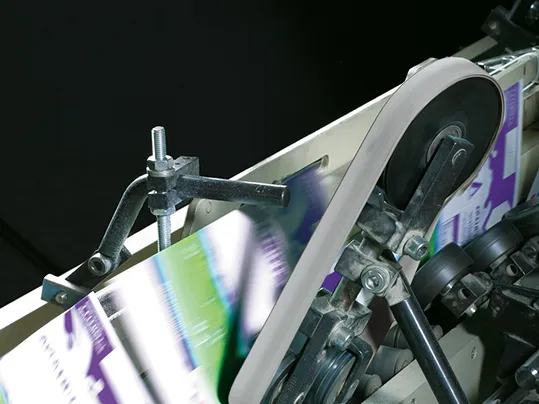

Applying hygienic and permanent markings to conveyor belts taps into new ways of enhancing process efficiency. As a result, exact positioning is never a problem – any shape or mark can be applied.

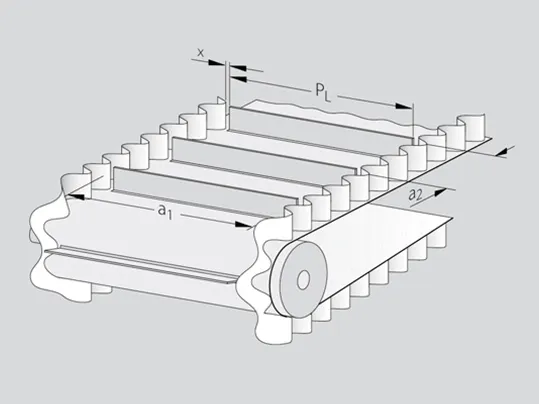

We offer a range of sidewalls, developed for the requirements of the food industry, for inclined or steep conveying of confectionery, flour or sugar for example. Their high level of resistance to oils and grease, as well as cleaning agents and disinfectants, guarantees safety all along the line.

Ref. No. 120

PDF | EN | 204 KB

HighGrip is a special type of surface coating that ensures perfect product grip, easy splicing methods and a very strong top face. HighGrip belts are especially suitable for inclined conveying.

Ref. No. 191

PDF | EN | 348 KB

Homogeneous, elastic belting material made of urethane can be used on a number of applications such as spreaders or check-weighers. In addition to ideal tracking, Forbo’s elastic belts have excellent release characteristics, great troughing capabilities and dimensional stability.

Ref. No. 205