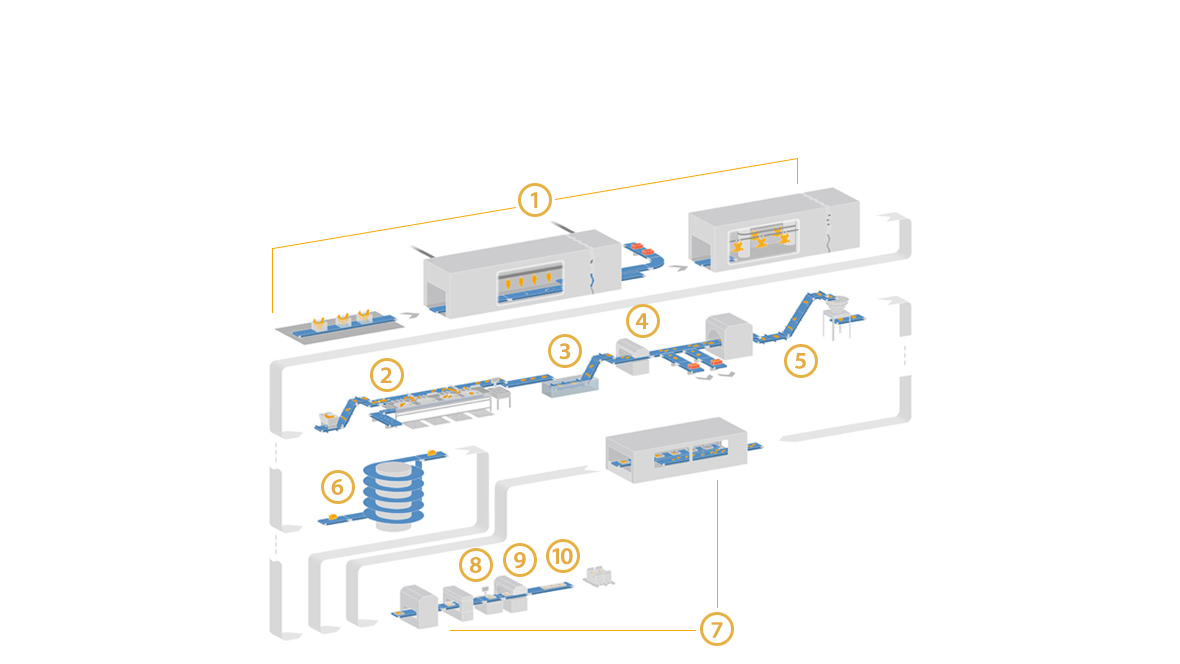

How poultry is processed

To guarantee top-quality products, poultry processing needs to be exceptionally precise, hygienic, and efficient.

The role conveyor belts play is often underestimated but important nevertheless. Because they ensure uninterrupted, systematic production. From delivering animals to final packaging, the belts help make the whole process seamless and synchronous.

Which is why it’s all the more important to choose, maintain, and properly use the appropriate processing belts. Find out the conveyor belts that are right for you at each poultry-processing step.

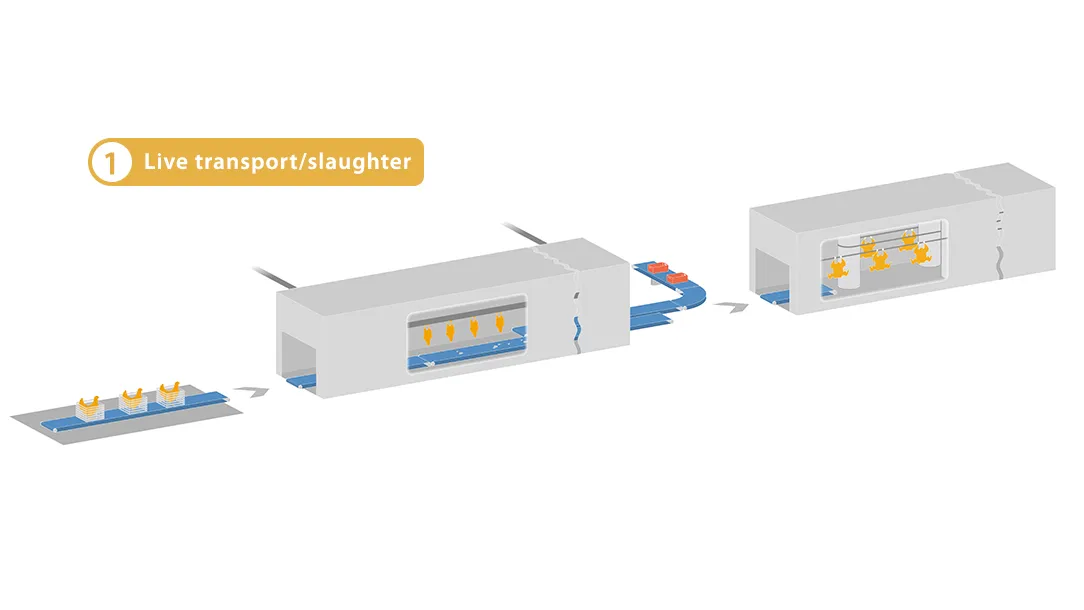

Once the live animals have arrived, they are stunned, slaughtered, plucked, and gutted in compliance with animal welfare regulations. Then they cool down and, depending on the machinery, are jointed in separate stations.

Technical Requirements of the Belts

Live transportation of birds requires very tough belts. Because they are frequently cleaned to remove animal excrement, they need to be resistant to abrasion and chemicals and hard wearing. It’s also useful if they are UV resistant and easy to repair. When belts transport slaughterhouse waste, their mechanical requirements are less critical. Nevertheless, belts conveying offal for processing must comply with exacting hygiene standards. Food-grade conveyor belts are also a must for conveying and processing offal and slaughterhouse waste.

Our solution

We have coatings and belt designs that can handle any task at this step in the process.

We recommend our Prolink plastic modular belts for transporting live birds. These belts are made of hard-wearing, chemical-resistant polyethylene (PE), for instance, series 6.1.

A range of easy-to-clean belt types are ideal for slaughterhouse waste. Our portfolio offers various, exceptionally hygienic, EU- and FDA-compliant HACCP belts for conveying offal in particular.

Contact us if you’d like to know more

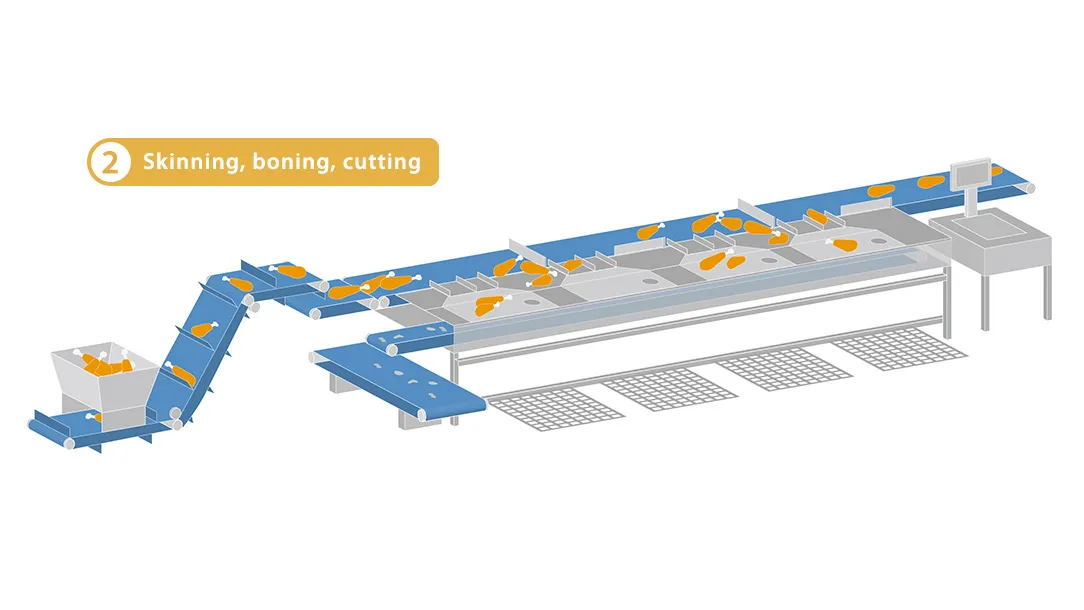

At this stage, the animal is skinned, the carcass removed if necessary and the poultry jointed in line with final product specifications. Meat and by-products are then inspected and transported in crates or on a conveyor belt.

Technical Requirements of the Belts

Just like all areas of the food industry, food-grade conveyor belts are required here too. To skin the poultry, the belt types between the upper and lower belt need to be as robust as possible. To bone and joint the meat, incision-resistant belt surfaces are essential.

Our solution

For skinning poultry, Prolink series 4.1 plastic modular belts made of chemically resistant and food-grade polyethylene (PE) have a good track record. They offer outstandingly secure tooth engagement and have a small end diameter. The whole design of the module and sprocket is easy-to-clean down to the last detail. Flights boost the top belt’s lateral stiffness.

We recommend our Prolink plastic modular belts made of incision-resistant polyoxymethylene (POM) CR (cut resistant) for boning and jointing. Depending on the method, you can also use our fabric-based belts with incision-resistant surfaces (polyurethane).

These are easy to clean and our Smartseal belt edge sealing can also provide extra protection from fraying. Both are ideal when rotary cutters are used.

If required, all belt types can be spliced on the machinery itself. And splicing Prolink plastic modular belts requires no special tools. We offer various splicing methods and tools for fabric-based and homogenous belts.

Contact us if you’d like to know more

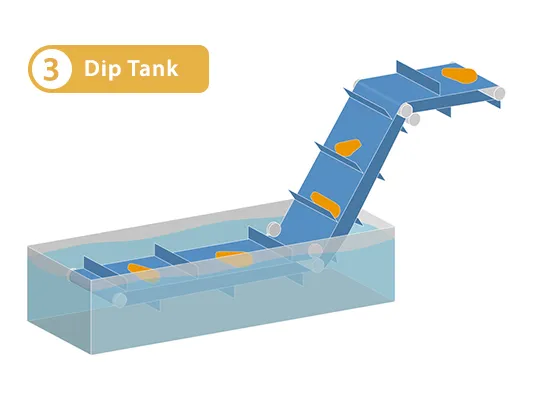

Some countries stipulate dipping meat to prevent contamination. The slaughtered poultry is rinsed in chilled chlorinated water and disinfected. The chlorine dioxide kills germs such as salmonella and campylobacter in broiler, chicken and poularde meat.

Technical Requirements of the Belts

Dip tank conveyors require belts that are resistant to peracetic acid and chlorinated disinfectants. Belts used in dip tank conveyors must have exceptional chemical resistance. Their drainage characteristics should also allow chlorinated water to drain off easily.

Our solution

Depending on the conveyors, you can use our range of food-grade, easy-to-clean plastic modular belts and sprockets. Numerous belts with large open areas are made of very chemical-resistant polyethylene (PE). They also have long service lives for this demanding process.

Contact us if you’d like to know more

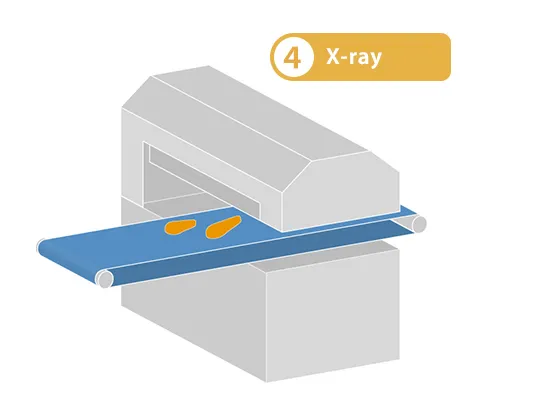

How do you make sure your meat and poultry doesn’t contain any glass, bones, or stones? X-ray detectors inspect your products for contamination. The also perform quality control checks.

Technical Requirements of the Belts

The belts must be food grade, but a high friction coefficient on the top face is also an advantage. This feature improves positioning stability when the belt passes through the lead or lead substitute curtain.

Our solution

The FRT (closed surfaces with friction tops) versions of our Prolink plastic modular belts achieve a very high and therefore beneficial friction coefficient. But even with our Transilon conveyor and processing belts, numerous belts with suitable surface coatings (e.g. rhomboid patterns, silicone) achieve the friction coefficient required.

Our belts guarantee efficient, perfect processes and therefore no faulty measurements.

Contact us if you’d like to know more

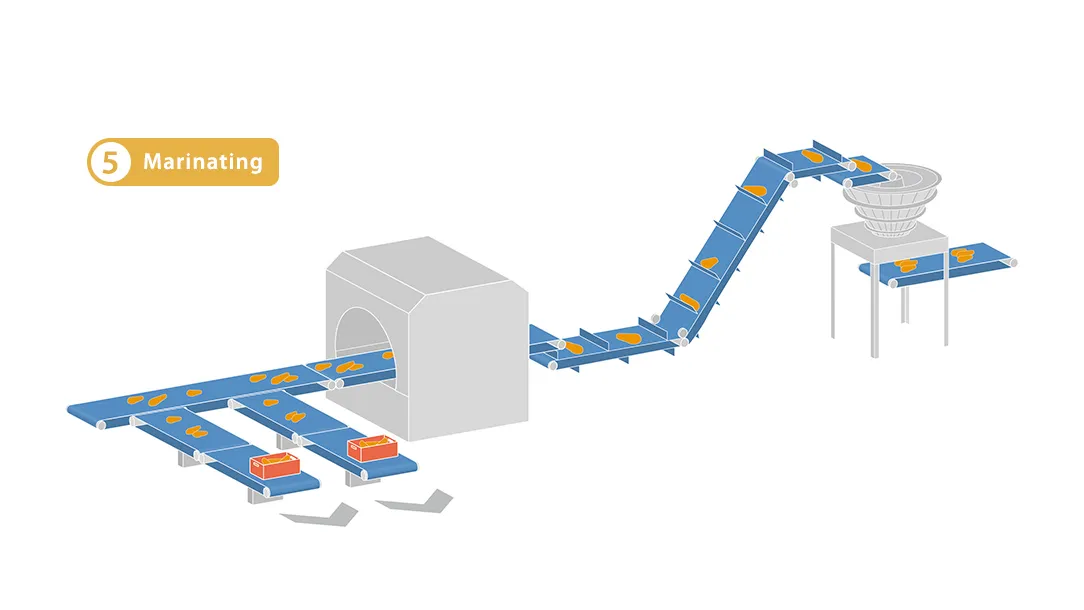

Now it’s time to put the finishing touches to the products. They are marinated, formed, or breaded. And are check-weighed and transported between each processing station. Other belts remove any waste that occurs in the process.

Technical Requirements of the Belts

Each step in the process requires specific belts. Belts used during marinating need to be food grade and have large open areas. Forming processes require hard-wearing belts with good release properties. During the weighing process, belts must always be the same thickness because varying belt weights will impact the meat’s weight. Consequently, you’ll achieve the product quality desired and comply with the standards.

Our solution

Our ranges offer multiple belt types geared to this process.

When hygiene’s critical, our belts are designed and come in materials that make them child’s play to clean. For instance, we have easy-to-clean Prolink plastic modular belts, belt edge sealing for fabric-based types, as well as homogenous belts.

Special belt types and fabrications ensure excellent drainage as well as high-strength, homogenous splices.

All the belts we recommend comply with your HACCP concept to the letter.

Metal mesh or grid belts are used for breading, but are not from our own product range.

Contact us if you’d like to know more

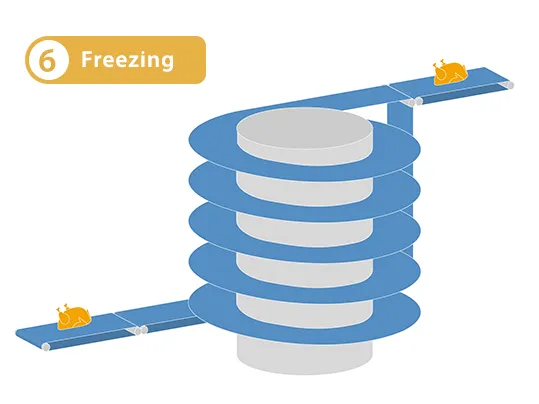

Many sales channels require deep-frozen products.

Linear or spiral freezing systems cool them down to the requisite temperature. Cardboard or plastic packaging are customary for shipping.

Technical Requirements of the Belts

In deep-frozen sections, the belt must still be flexible and not become brittle at temperatures down to -40°C. To ensure it doesn’t hamper the cooling process, the belt carcass must have an open area and be easy to repair if necessary.

Spiral freezers also require belts that are suitable for curves.

Our solution

Our Prolink plastic modular belts made of temperature-resistant polyoxymethylene (POM) and polyethylene (PE) are ideal for deep-freezing applications. For short cooling sections, the Prolink product portfolio includes linear and curved modules with large open areas. Series 5 has all these features. It’s ideal for curved and straight conveyor sections and has an open area of up to 45% for good airflow and drainage.

To withstand the high tensile forces in cooling towers, we add stainless steel hinge pins to our curved Prolink belts.

Contact us if you’d like to know more

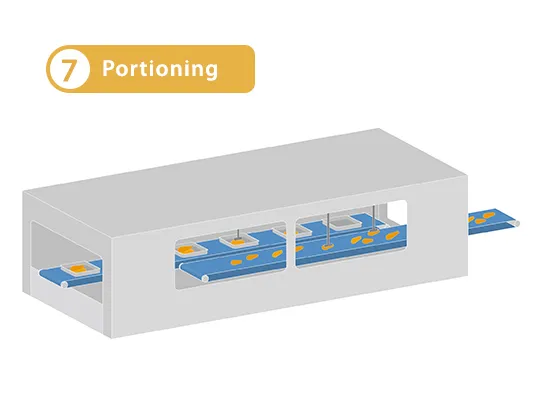

Your products are now portioned into units, packaged in bags or trays and ready for sale. The products are then shrink-wrapped and (depending on the system and product) labeled, wrapped and repackaged.

Technical Requirements of the Belts

Food-grade, easy-to-clean belts are a must. But they need to have other characteristics too. For instance, for weighing processes, belt thickness must be identical and the surfaces able convey and position products reliably. They should also be heat-resistant if shrunk-wrapped.

Our solution

Our special belts also help you to complete these processing tasks successfully as well. At the same time, they meet your HACCP concept’s requirements.

Our check-weigher belts’ functional surfaces guarantee dependable conveying and precise positioning of products. They stand apart because their thickness is the same. And very precise splices make endless belts superfluous. Temperature-resistant belts are ideal for shrink tunnels. For these steps, the Prolink and Transilon series are alternatives.

Contact us if you’d like to know more

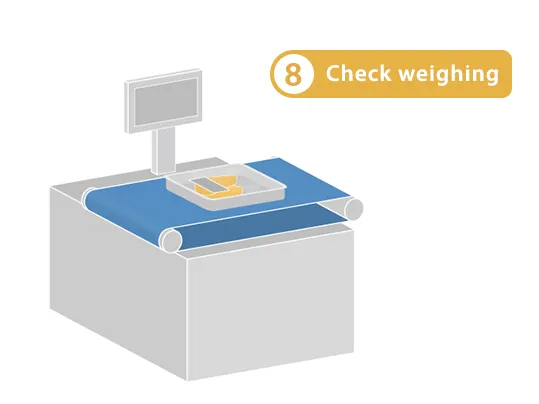

Weight is usually inspected inline using check-weighers. It doesn’t matter whether your products are packaged or unpackaged.

Technical Requirements of the Belts

The conveyor belt’s hygiene standards vary, depending on whether packaged or unpackaged meat is weighed. The same applies to the quality of the belt and the fabrication. How to minimize check-weighing errors.

The belt’s thickness must be identical – splices must be flat across the whole area. Thin belts are ideal for check-weighing, allowing minimum end diameters and very precise measurement results.

Our solution

Our Transilon conveyor and processing belts come in various designs with maximum thickness consistency. Exact fabrication guarantees the same surface weight, even in the area where the splice is. Because their thickness is consistent and splices precise, you can easily use our check-weigher belts instead of endless ones. On request, we can seal the edges of our fabric-based belts to meet the most stringent of hygiene standards.

What’s more, elastic belts with homogenous product designs and easy-to-clean surfaces are predestined for use in check-weighers. They are very flexible and elastic, keep sufficiently taut to enable perfect tracking and require no additional take-up units. We also supply these elastic belt types endless with maximum splicing precision (thickness uniformity).

Contact us if you’d like to know more

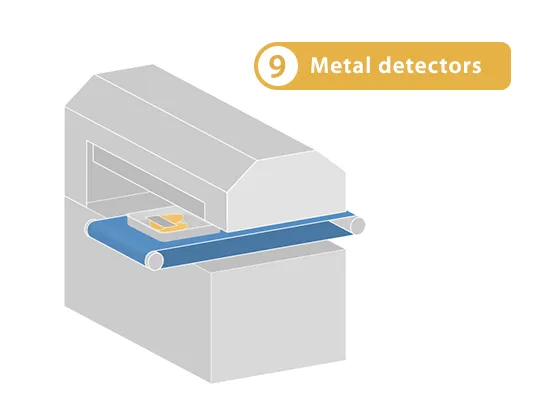

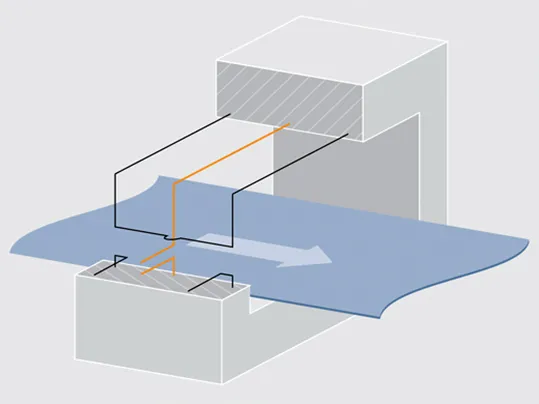

During final inspections, you check your products for contamination by foreign bodies. Metal detectors help guarantee that the final product contains no metallic objects.

Technical Requirements of the Belts

To ensure metal detectors only find contamination in products, these belts mustn’t contain anything that could distort the test result. At this stage, there must be no metallic substances or compounds in the belt.

Our solution

Depending on the design and the metal detector’s sensitivity, you can choose various Prolink plastic modular belts with plastic hinge pins, Transilon conveyor and processing belts as well as homogenous belts. Our antistatic belts and transparent plastic modular belts are ideal for this application.

Contact us if you’d like to know more

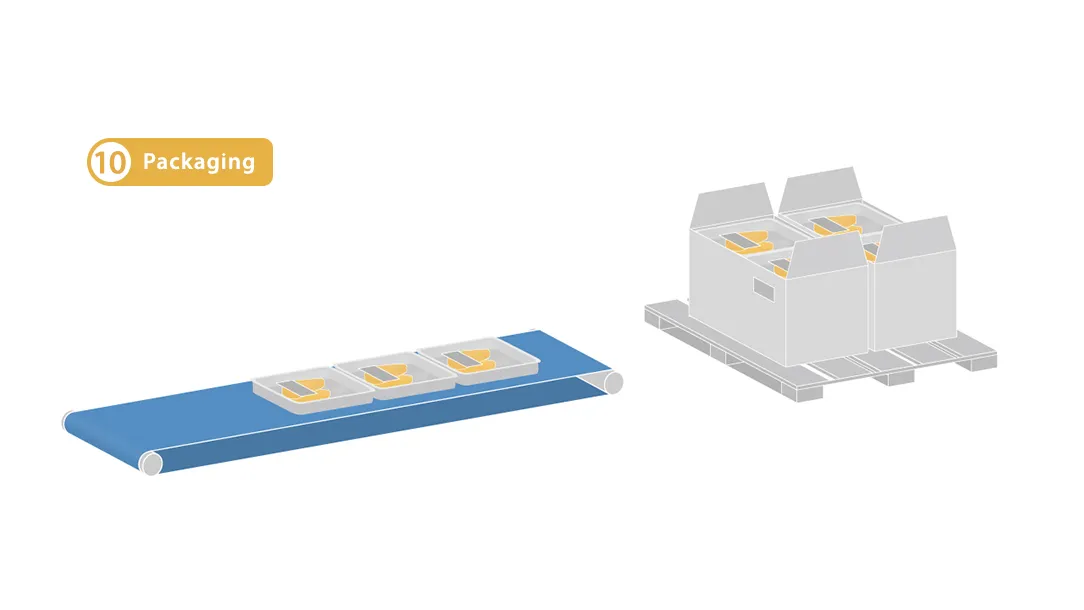

This final step in poultry processing involves packaging products and preparing them for shipping. We’ve condensed lots of the processes because they vary widely depending on the type of packaging. There are lots of methods such as shrink wrapping to (re)packaging in boxes and palletizing.

Technical Requirements of the Belts

Depending on the process and how your products are conveyed, the parameters specific to the conveyor govern the technical requirements. For example, very elastic belts might be beneficial in some process while exceptional tensile strength might be essential in others.

Our solution

We supply both fabric-based belt types and plastic modular belts for any sub-process. We can easily fit many belts from this portfolio to your packaging systems. As a result, you’ll be able to exploit your productivity potential and ability to produce quality products to the full.

Robust belts with long service lives guarantee reliable processes and HACCP-compliant belts allow direct contact with food. At this step in the process, the belts meet stringent hygiene requirements at all times.

Contact us if you’d like to know more

Poultry processing is complex and every detail counts. Conveyor belts play a key role from the get-go.

We’ll recommend the right belt so that you can achieve consistently top product quality. Your conveyor’s size is not very important because we can splice all our belts on the conveyor itself. With our Prolink plastic modular belts this is child’s play because we require no special tools to do so. We can offer a range of splicing methods and tools for fabric-based and homogenous belts too. As a result, poultry processing is flawless and efficient.

Our fabric-based conveyor belts, plastic modular belts or homogenous belts allow you to meet stringent hygiene standards at every stage and achieve maximum efficiency and product quality.

Any questions about our poultry processing products? Then contact us.

To the contact form